Pilot Plant Equipment: An Overview Guide – Armfield

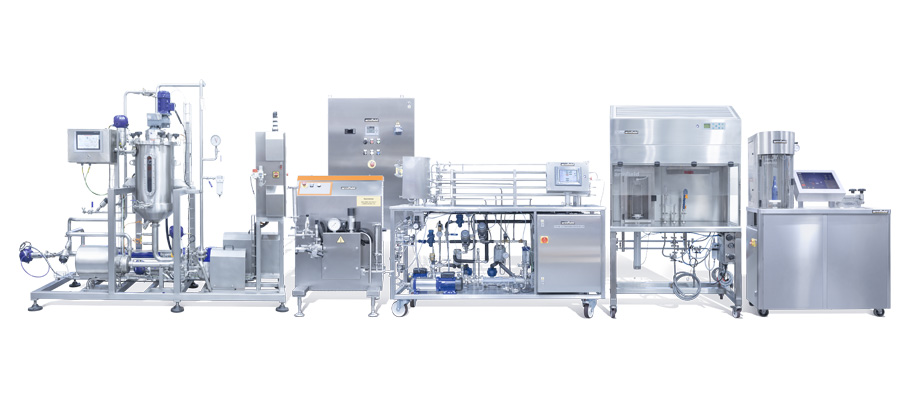

Pilot plant equipment plays a crucial role in the food industry, acting as a bridge between small-scale lab experiments and full-scale production. At Armfield, we provide top-tier solutions for industrial food technology, emphasising the importance of both high quality materials, process control and repeatability. This guide explores the significance, types, and considerations of this kind of equipment, particularly focusing on its application in the liquid food sector.

What is a Pilot Plant?

A pilot plant is a small-scale version of a production plant used to test and optimise new processes and products. Unlike lab experiments, which often involve very small quantities, this type of equipment simulates industrial conditions to provide realistic data on how a process will perform on a larger scale. They are crucial for refining recipes, improving efficiency, and ensuring the feasibility of scaling up from prototype to full production.

The Importance of Such Equipment

Our plant equipment is integral to the development of new food products and processes. It allows for experimentation and validation in conditions that closely mirror those of a full-scale production environment. This step is essential for identifying potential issues, testing variations, and ensuring that new processes are both effective and economically viable before committing to large-scale production.

Types of Pilot Plant Equipment

Armfield offers a comprehensive range of equipment specifically designed for research, development, and small-scale production in the food and beverage industries. These systems cater to processes such as pasteurisation, sterilisation, mixing, drying and more. Here’s an overview of the key equipment offered in this range:

Heat Treatment Systems (HTST, UHT and Pasteurisation)

- Carbonators (including filling and capping)

- Spray Dryers

- Homogenisers

- Mixing and Blending Equipment

- Continuous SSHE crystallisers

- Filtration Systems

- Oils refining

Desolventising – Bleaching – Neutralising – washing – Hydrogenation – Deodorising

Distillation Columns

For processes requiring separation or purification, distillation columns are indispensable. In the food industry, they can be used to concentrate flavours, remove impurities, or separate components of a mixture. These columns must be designed to handle varying flow rates and temperatures, reflecting the complexities of large-scale operations.

Key Features and Capabilities

Pilot plant equipment must be designed with features that support scalability and efficiency. Key considerations include:

- Size and Capacity: Equipment must be appropriately sized to handle the quantities required for testing without compromising the quality of the results.

- Materials: The choice of materials for construction affects durability, safety, and compatibility with various food products. Stainless steel 316 is commonly used due to its resistance to corrosion and ease of cleaning.

- Control Systems: Advanced control systems allow for precise monitoring and adjustment of process parameters, ensuring accurate replication of industrial conditions.

Selecting and Designing Pilot Plant Equipment

Choosing the right pilot plant equipment involves several factors:

- Scalability: Equipment should be designed to facilitate easy scaling up from small batches to full-scale production. This involves considering how process parameters and equipment performance will change as scale increases.

- Cost-Effectiveness: While high-quality equipment is essential, it should also be cost-effective. Balancing initial investment with long-term benefits and operational costs is crucial.

- Customisation: Depending on the specific needs of the food product or process, some degree of customisation may be required to optimise performance.

Industries Utilising Pilot Plant Equipment

This equipment finds applications across various industries, including:

- Food and Beverage: Essential for developing new recipes, improving processing techniques, and ensuring quality control.

- Pharmaceuticals: Used for testing drug formulations and production processes.

- Chemical Manufacturing: Facilitates the development and optimisation of chemical processes.

Benefits of Using Pilot Plant Equipment

Utilising pilot plant equipment offers numerous advantages:

- Risk Reduction: By testing processes on a smaller scale, potential issues can be identified and addressed before committing to full-scale production.

- Cost Savings: Early detection of problems can prevent costly production errors and ensure more efficient use of resources.

- Improved Quality: Pilot plants enable fine-tuning of processes to enhance product quality and consistency.

Operating and Maintaining Pilot Plant Equipment

Proper operation and maintenance of pilot plant equipment are crucial for reliable performance. Key practices include:

- Regular Maintenance: Routine checks and maintenance help prevent breakdowns and extend the lifespan of the equipment.

- Safety Precautions: Adhering to safety guidelines ensures the well-being of operators and the integrity of the equipment.

- Troubleshooting: Common issues such as leaks or malfunctions should be addressed promptly to avoid disruptions in testing.

Troubleshooting Common Issues

When problems arise with pilot plant equipment, common issues include:

- Leaks: Often caused by worn seals or faulty connections. Regular inspections and timely repairs can prevent leaks.

- Malfunctions: Equipment may fail to operate correctly due to electrical or mechanical issues. Diagnostic tools and professional support are essential for effective troubleshooting.

Summary

Pilot plant, equipment is a cornerstone of innovation in the food industry, facilitating the development and refinement of new products and processes. At Armfield, we offer comprehensive solutions designed to meet the evolving needs of industrial food technology. Our focus on training and teaching ensures that users are equipped with the knowledge to maximise the benefits of pilot plant equipment.

For more information on how our pilot plant equipment can support your food industry projects, contact us today.

One thought on “Pilot Plant Equipment: An Overview Guide – Armfield”

Comments are closed.