PCT40 Range – Multi-function Process Control Teaching System

The PCT40 contains everything that is needed to perform a range of single-loop process control experiments in conjunction with a PC.

Description

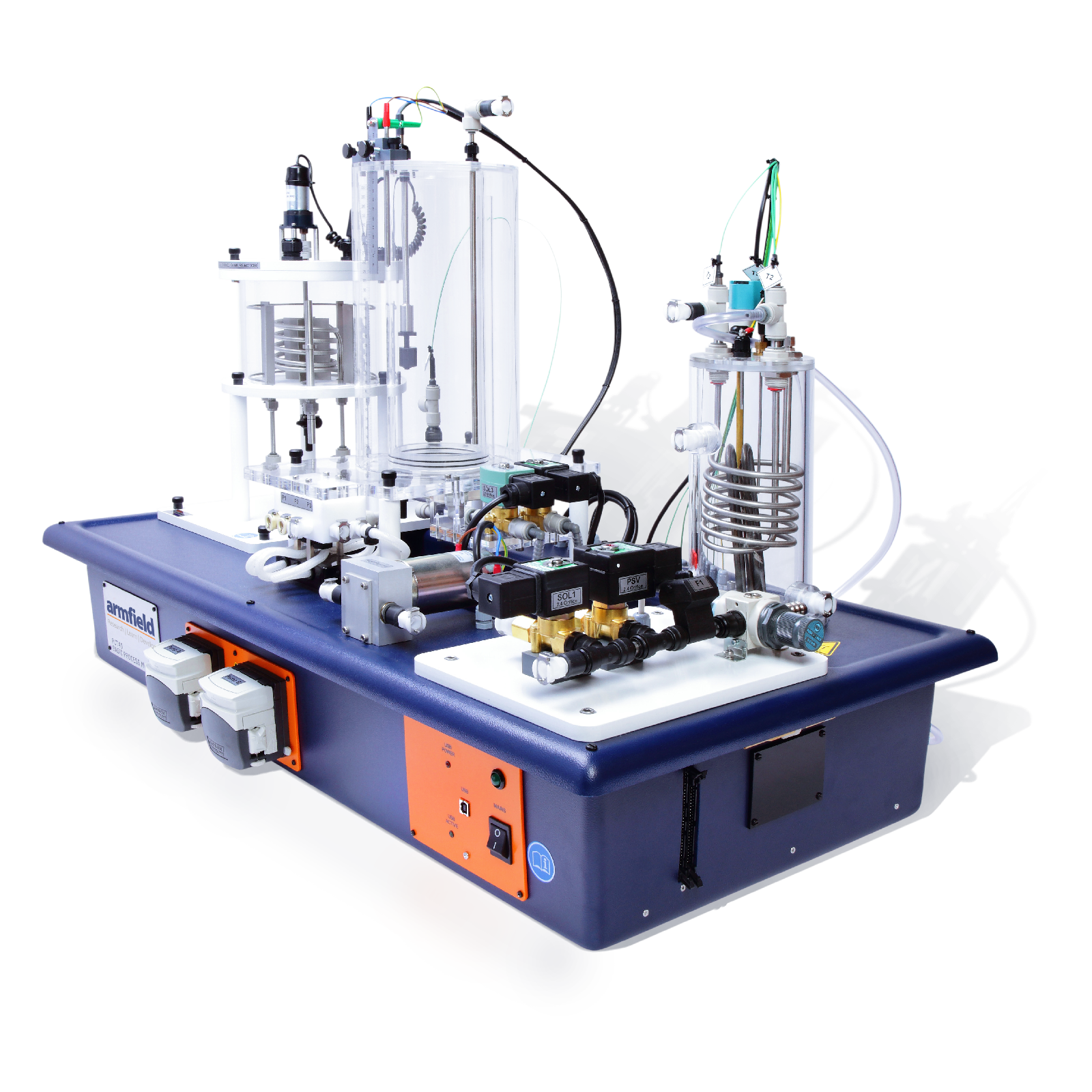

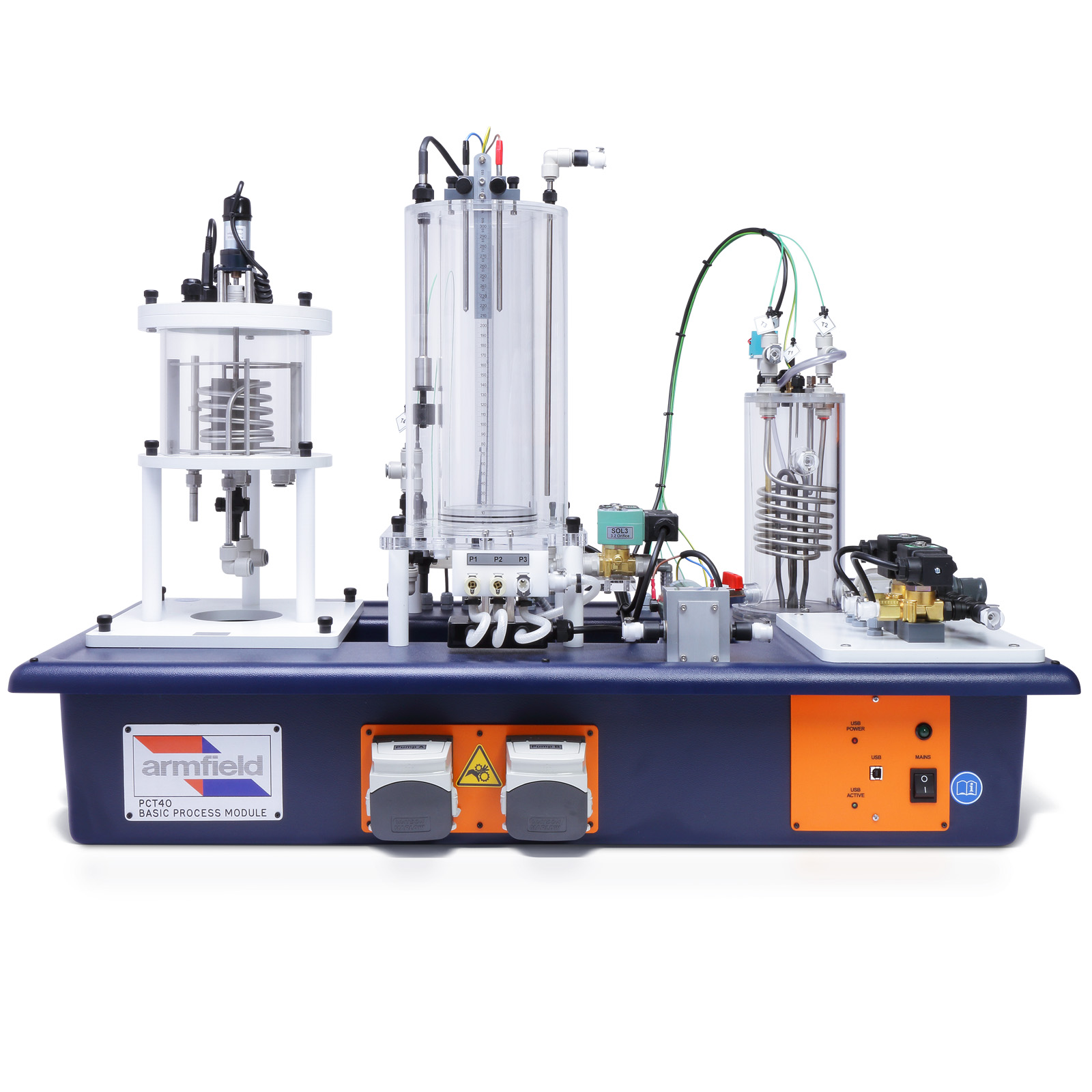

PCT40 Basic Process Control System

The PCT40 contains everything that is needed to perform a range of single-loop process control experiments in conjunction with a PC.

It includes a variable volume process tank, a hot water tank with electric heater and indirect heating/cooling coil, a hot water pump, two non-dedicated pumps, three on/off solenoid valves and a proportioning valve. The instrumentation includes temperature sensors, two differential water pressure sensors, a mechanical level sensor (float switch) and an electronic level sensor (conductivity). The inlets and outlets of the various pumps, valves and tanks incorporate self-sealing quick release fittings. This enables the configuration to be quickly changed, offering a wide variety of different loops.

The PCT40 includes a computer interface (USB), and all of the parameters can be controlled directly from the computer, (i.e. the pump speeds, the valve positions and the heater power). The computer also displays the readings from the various measurement sensors.

The software supplied with the unit includes on/off, time proportioned and proportional/integral/derivative (PID) algorithms where all the parameters are easily accessed and adjusted by the user. This approach means that a separate electronic console is unnecessary for most applications.

The flexible nature of the system also enables a wide variety of different disturbances to be applied to the loops to permit the effectiveness of the control parameters to be compared. As all these disturbances are under software control, they can be repeated precisely during the optimisation process, thus enabling an excellent degree of fine-tuning to be implemented.

A pressure regulating valve with filter is also included to isolate the equipment from fluctuations in the water supply pressure.

The type of loops achievable with the basic PCT40 include:

- Tank water level by varying input flow

- Water flow rate by varying pump speed

- Temperature of water in a vessel by varying the heater power

- Temperature of water heated indirectly by varying the flow rate

(All these loops are under software control)

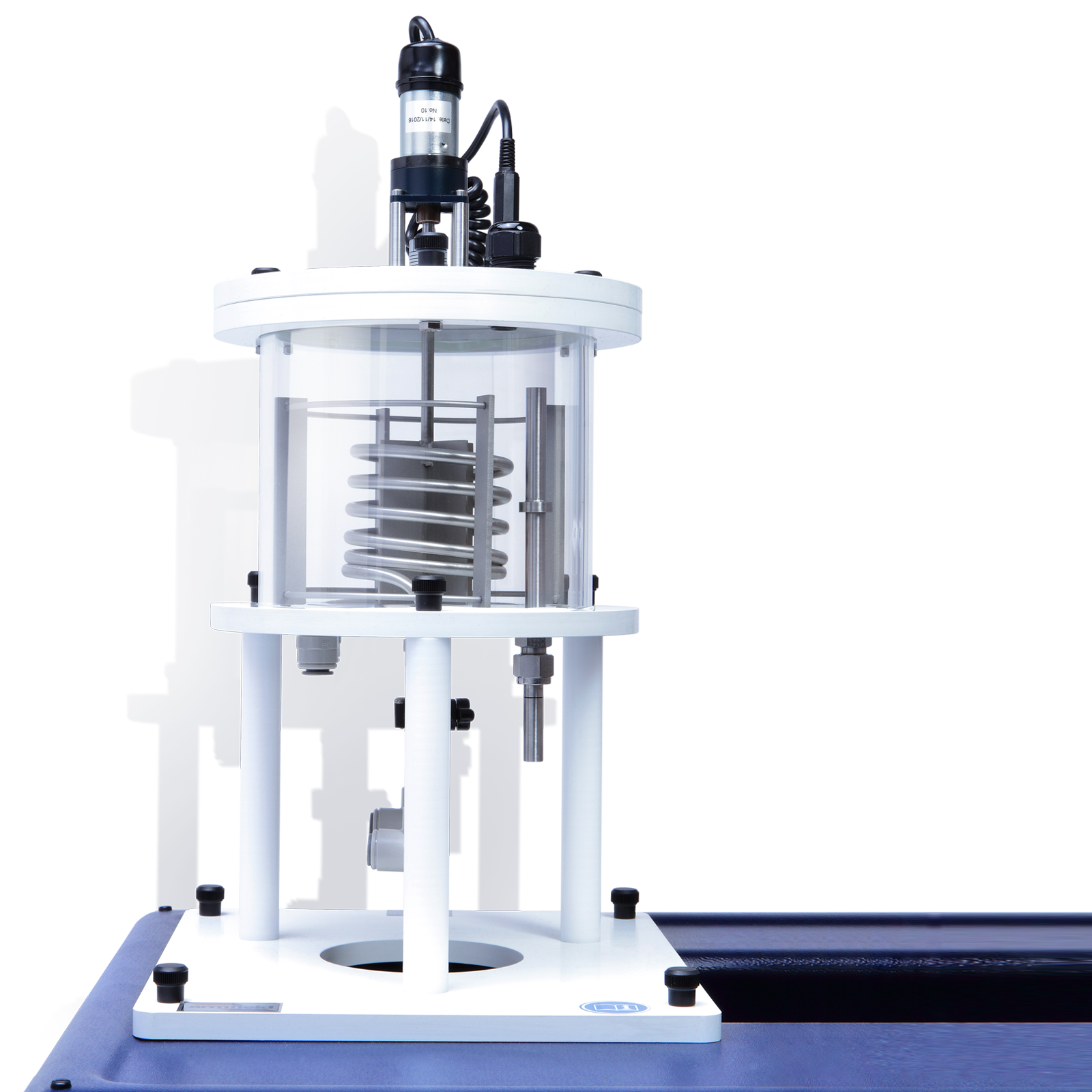

PCT41 Process Vessel Accessory

The PCT41 extends the capability of the basic PCT40 by adding an additional process vessel, complete with a heating/cooling coil and a stirrer. The inputs and outputs incorporate quick release fittings, enabling the PCT41 to be added quickly and easily.

The PCT41 also includes a conductivity probe to enable cost-effective fluid property demonstrations to be performed.

The addition of the process vessel enables more complex process control problems to be addressed, including remote set point demonstrations. Again these all take place with the repeatability advantages that electronic and software control brings.

Additional loops that can be implemented with the PCT41 include:

- Single loops in combination:

- Conductivity control of reactor contents by varying flow rate of one component

- Temperature control of reactor contents by varying heating fluid flow rate

- Temperature control of heating fluid by varying heater power

Remote set point control:

- Ratio control of two flows (Fig 1)

- Cascade control of conductivity and flow (Fig 2)

- Feed-forward control of flow to flow

- Feed-forward control of flow combined with feedback control of conductivity

(All these loops are under software control)

PCT42 pH Sensor Accessory

The PCT41 includes a conductivity probe as part of the basic supply. This conductivity probe can be used to demonstrate fluid property control systems without the maintenance problems, which can be experienced with pH probes. However, as pH control is probably the most common industrial application of this type of control system, users may wish to implement true pH control loops. This can easily be implemented by adding the PCT42 pH Sensor Accessory to the combined PCT40 + PCT41 systems.

PCT43 Electronic Console

The PCT43 is an electronic console that can be used to control the PCT40 (+PCT41/42) instead of a computer. It includes controls for the pumps, valves and heater, plus a display for the sensors. It incorporates a commercial PID controller, complete with RS232 interface. Other facilities include four 20mA interfaces and selector switches to enable many of the different configurations to be implemented without using external jumper connections.

The PCT43 enables all of the PCT40 and PCT41 single-loop configurations to be implemented without using a computer. Using this console also enables the sensor data to be logged and displayed on a computer (using the PCT40 USB interface), but with the control functions being implemented in the PCT43 hardware, rather than the computer software.

Facilities include:

- Use of a commercial PID controller

- Simple interfacing to other PLC and/or PID controllers

- Use of four 20mA interfaces

- Use of serial communications (RS232) in a control system

- Simple SCADA demonstration (requires PC)

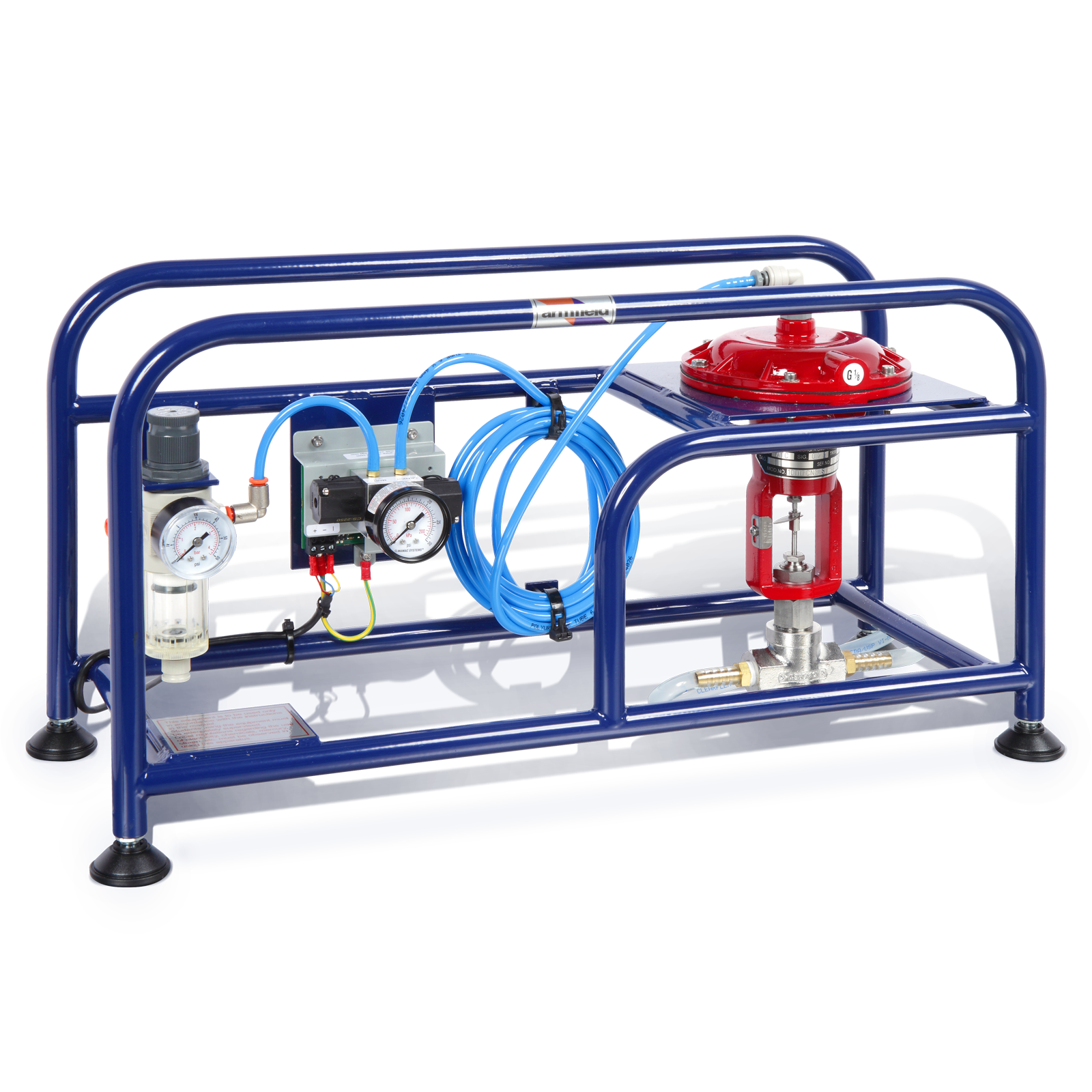

PCT44 Pneumatic Valve Module Accessory

The PCT44 is a pneumatic control valve, plus associated components, for use with the PCT40/41 system. Retaining the flexible concept of the whole range, it can be plumbed into many of the flow control loops, and provides a good illustration of pneumatic valve technology.

Note: This accessory requires a compressed air supply

Technical Specifications

Features & Benefits

- The basic PCT40 is used under computer control to demonstrate a variety of single control loops. It can be quickly reconfigured between processes, such as level control, temperature control, flow control and pressure control. The advanced software enables the student to change the control parameters, record results and analyse the results for the different configurations

- The PCT41 expands on the capabilities of the PCT40, and offers a wider range of control loops and strategies, including remote set points, dual loops, and fluid property control (using conductivity). Again all of these are under software control

- Other accessories are available, including a control console with commercial PID controller, plus a pH probe and a pneumatic valve for those wishing to implement specialised demonstrations

- Large range of demonstrations – configurable by the end user

- Computer control as standard

- Computer generated loop disturbances for repeatability, enabling small variations in control parameters to be investigated

- Flexible system, suitable for project work

The system is supplied with a complete educational software package with a wide range of facilities and functions. For most applications the computer is the primary interface between the user and the equipment.

The software displays real-time process mimic diagrams, with readings of the relevant sensor outputs, and controls for the system inputs. The on/off, time proportioned and PID control algorithms are accessible through ‘pop-up’ control boxes, which give the user access to all the key control parameters, including the proportional band, the integral time and the derivative effect.

The software is supplied with detailed mimic diagrams, and full instructional help texts for ten predetermined student exercises when using PCT40 and an additional four exercises when using PCT41. These predetermined strategies have been carefully chosen to illustrate a wide range of the system capability and possible control strategies, ie level, flow, temperature, pressure, fluid characteristics, single PID loops, cascade and multiple loops, remote setpoints, etc. However, because of the flexibility of the system, many more control situations are configurable than it is possible to provide predefined student exercises for. Because of this, Armfield have included a user configurable option with the software, which enables the full range of capability from the system to be explored. This is particularly useful for student project work.

Whichever configuration is being used, the software provides powerful data logging and graph plotting facilities, together with sensor calibrations and a wide variety of display and data export options.

The computer communicates to the PCT40 using a standard universal serial bus (USB) interface.

When used with the PCT43, the software also provides a simple SCADA demonstration. The process is controlled using the PID controller in the PCT43, but the P, I & D values can be accessed and varied by the computer, using the RS232 interface. At the same time the status of the process can be displayed on the computer by using the USB interface for data logging only.

Universal Software Interface

For users who wish to write their own software, eg in Matlab or LabVIEW™, full instructions are given for communications with the PCT40 via its built in USB interface. Advanced users are also given the facility to include their own process control algorithm, written in a suitable language such as C++. This is useful for exploring advanced and non-linear control systems.

It is possible to control the PCT40/41 loops using external PLC devices or PID controllers. These can be connected directly to the PCT40 for specific configurations. However, with the PCT43 electronic console it becomes very easy to connect up the inputs and outputs to enable a range of loops to be demonstrated.

PCT23MkII Process Plant Trainer

The PCT23MkII is a bench top process plant trainer used extensively in undergraduate engineering education and for training plant supervisors and operators.

It uses an industrial HTST pasteurisation plant to demonstrate a complete range of process control methods and strategies as used in industry.

The trainer incorporates an industrial style three stage plate heat exchanger with chevron plates for increased turbulence and efficiency. A conductivity sensor enables concentration measurement.

Software Requirements

- PCT40

- PCT23

- UOP3

Mains electrical supply:

110 to 240 V, 50 or 60 Hz

(Note, the units are supplied with¬ IEC leads to suit European and UK 230V, 50Hz outlets and USA 115V, 60 Hz outlets.)

PC computer with 2 spare USB ports (not supplied by Armfield) or external controller (PCT54 or PCT55)

A multi-function process control teaching system, capable of demonstrating level, flow, pressure and temperature control loops

• Bench mounted and includes a built-in USB computer interface

• Options include: reactor vessel with conductivity measurement, pH measurement, pneumatic control valve and electronic console

• Includes the following process control demonstrations:

Process principles

-

- Calibration of sensors (via PC software)

- Inflow control

- Outflow control

- Direct heating

- Indirect heating

- Batch operation

- Continuous operation

- Effect of sensor lag (eg thermometer pocket)

- Effect of system time constant (eg volume change)

- Effect of dead time (eg holding tube)

- Effect of mixing/stirring (requires PCT41)

Measured variables

-

- Level – on/off switch (fixed hysteresis)

- Level – differential on/off switch (adjustable hysteresis)

- Level – proportional pressure sensor (slow system response)

- Flow – proportional turbine sensor

- Temperature – on/off switch (fixed hysteresis)

- Temperature – proportional thermocouple sensors

- Static pressure – proportional sensor (fast system response)

- Differential pressure – proportional pressure (fast system response)

- pH – proportional sensor(requires PCT41 and PCT42)

Controller types

-

- Manual control

- Effect of reverse/direct action

- On/off output with hysteresis

- Time proportioned output with adjustable P, I & D terms and cycle time

- PID proportional output with adjustable P, I & D terms

- Remote setpoint control (requires PCT41)

- Ratio, cascade and feedforward with feedback loops (requires PCT41)

Controlled variables

-

- On/off flow control via solenoid valves

- Time proportioned flow control via solenoid valves

- Proportional flow control via pump speed

- Proportional flow control via electrical proportioning valve

- Proportional flow control via pneumatic proportioning valve (requires PCT44)

- On/off heater power control via solid state relay

- Time proportioned heater power control via solid state relay

- Proportional heater power control via solid state relay

PCT40 Basic Process Control System

Requires:

Single Phase Electrical supply:

- PCT40-A: 220-240V/1ph/50Hz

- PCT40-B: 110-120V/1ph/60Hz

- PCT40-G: 220-240V/1ph/60Hz

Personal computer or PCT43

Cold water supply (1.5 l/min at 2 bar)

PCT41 Process Vessel Accessory

Requires: PCT40

PCT42 pH Sensor Accessory

Requires: PCT40 and PCT41

PCT43 Electronic Console

Requires: PCT40

PCT44 Pneumatic Valve Module Accessory

Requires: PCT40

And a clean supply of compressed air of at least 21psi

PACKED AND CRATED SHIPPING SPECIFICATIONS

PCT40 Basic Process Control System

Volume: 0.4m³

Gross Weight: 40Kg

PCT41 Process Vessel Accessory

Volume: 0.1m³

Gross Weight: 20Kg

PCT42 pH Sensor Accessory

Volume: 0.01m³

Gross Weight: 3Kg

PCT43 Electronic Console

Volume: 0.1m³

Gross Weight: 15Kg

PCT44 Pneumatic Valve Module Accessory

Volume: 0.1m³

Gross Weight: 26Kg

PCT40 Basic Process Control System

Length: 1.0m

Width: 0.54m

Height: 0.7m

PCT41 Process Vessel Accessory

Length: 0.3m

Width: 0.25m

Height: 0.45m

PCT42 pH Sensor Accessory

Length: 0.012m

Width: 0.012m

Height: 0.12m

PCT43 Electronic Console

Length: 0.365m

Width: 0.27m

Height: 0.275m

PCT44 Pneumatic Valve Module Accessory

Length: 0.35m

Width: 0.35m

Height: 0.4m

- PCT40-A: 220-240V/1ph/50Hz

- PCT40-B: 110-120V/1ph/60Hz

- PCT40-G: 220-240V/1ph/60Hz

- PCT41

- PCT42

- PCT43

- PCT44