FT75 Laboratory Pasteuriser

The FT75 is an example of modern high-temperature, short-time (HTST) pasteurisers used in food production. Utilising a three-stage plate heat exchanger, it provides an excellent example of a production line approach to food manufacturing.

Description

The FT75 Laboratory Pasteuriser accurately reproduces in miniature the industrial High Temperature Short Time process (HTST). Nominal throughput is only 10 litres/ hour. Although primarily designed for use with milk, other food liquids can be pasteurised providing that their solids content is not too high.

Pasteurising temperatures and holding times are easily adjusted, allowing the effectiveness of the product treatment to be investigated. When correctly operated, cleaned and sterilised the FT75 can produce a correctly treated and pasteurised product. However it is not intended that this apparatus be used to manufacture products for human consumption.

The HTST process involves heating the process liquid (milk) to a minimum temperature of 72˚C, holding this temperature for 15 seconds and cooling to a storage temperature as quickly as possible.

The three stage plate heat exchanger of the FT75 (fig1) achieves these parameters by (1) heating the process liquid with hot water prior to its entry into the holding tube and then by (3) cooling with cold water to storage temperature. An intermediate heat exchanger (2) transfers heat from the treated product to the feed liquid. This provides dual benefits in reducing the energy required to reach the pasteurising temperature and in reducing the cooling required. An optional Armfield CW17 Chilled Water Circulator is available. Full instrumentation and controls are provided to regulate heating water temperature and also feed pump speed which in turn regulates holding time.

Optional computer linkage is available to control the process and to log production data.

A user instruction manual provides installation, commissioning and maintenance data together with project exercises. For secondary/high school use a full set of worksheets and simple explanations is available on request.

Technical Specifications

- A bench top miniature High Temperature Short Time (HTST) system for the demonstration of the industrial pasteurisation process

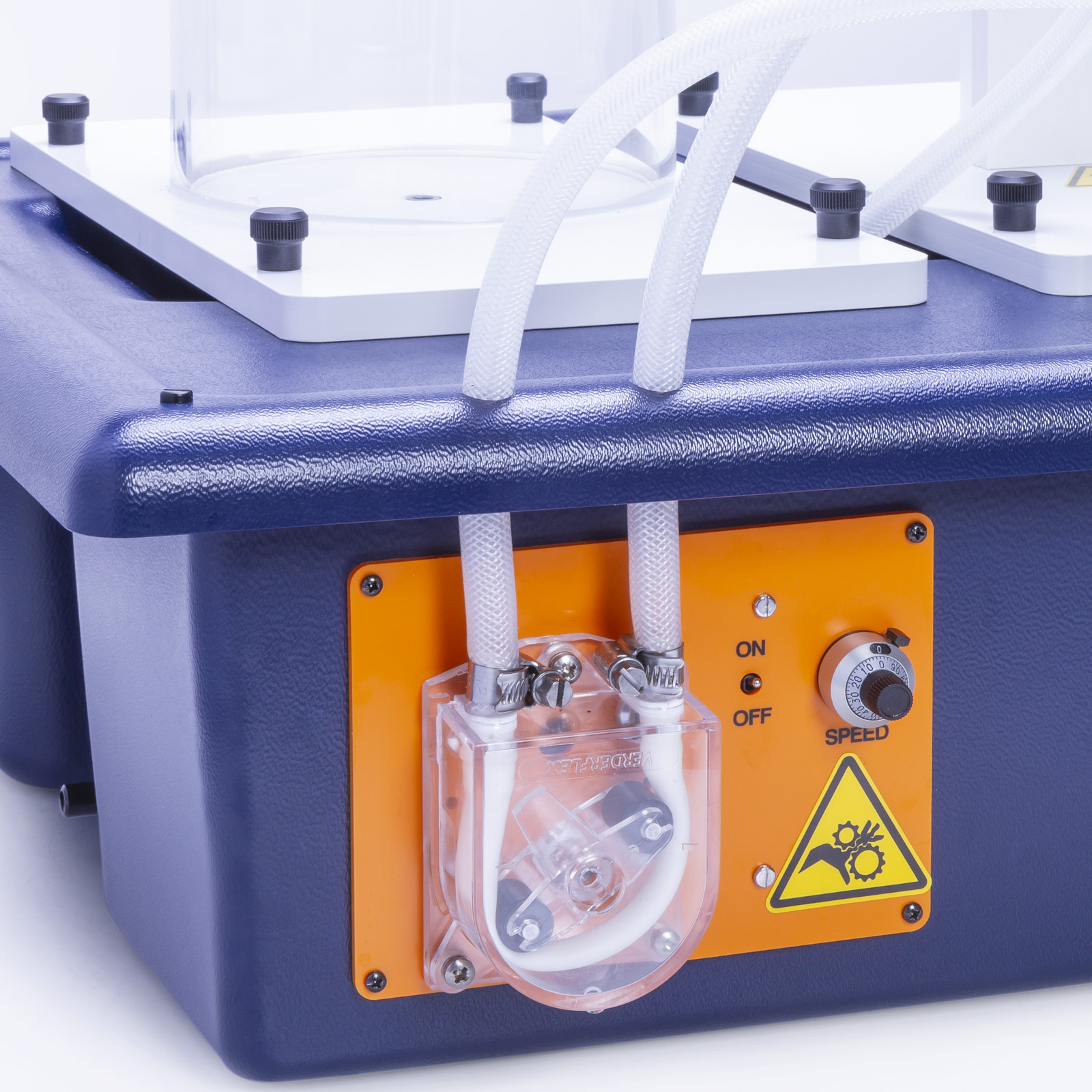

- Includes a transparent feed tank, a feed pump, a three stage heat exchanger, a holding tube, a divert system and a hot water circulator

- The feed pump is a peristaltic pump, with a variable speed control

- The heat exchanger is fully representative of large scale industrial units

- It uses stainless steel heat transfer plates

- It can be dismantled for examination and cleaning

- It comprises three stages, a final heating stage, a regeneration stage and a cooling stage

- Holding time is 15 seconds at 10 l/hr, in a stainless steel holding tube

- Process temperature is measured and controlled

- Hot water is circulated around the heating stage of the heat exchanger in a closed loop system

- A PID controller is used to adjust the electric water heater, keeping the product process temperature at the requested value

- Optional data logger with USB interface is available

Features & Benefits

The equipment illustrates a number of major messages associated with food such as ‘Food is a material’, manufactured in a factory and not in a kitchen; ‘Heat kills germs, cold doesn’t’ (including the importance of hygiene); ‘Energy efficient processes keep prices down and protect the environment’.

In addition to pasteurisation, the FT75 can be used to demonstrate a wide range of important issues in the field of food technology.

These topics can be covered at a simple introductory level and at much more sophisticated levels to suit higher educational needs.

- Continuous production process

- Pasteurisation of milk, comparison of raw and treated product

- Control of pathogenic bacteria, shelf life assessments

- In line logging/data monitoring

- Heat transfer

- Energy conservation, cost and environmental benefit Calibration

- Cleaning in place (CIP)

- Process control/feedback

- Quality assurance/quality control

- Links between technology and science

CW17: chilled Water Circulator

FT75-DTA-ALITE: data logging system Includes both hardware and software. Requires a PC running Windows 98 or above with a USB port.

STS5: additional temperature sensor (for use with data logger), up to two may be used for more sophisticated experiments involving quantitative analysis of heat transfer characteristics.

Electrical supply:

FT75-A: 220-240V/1ph/50Hz, 10A

FT75-B: 120V/1ph/60Hz, 20A

FT75-G: 220-240V/1ph/60Hz, 10A

Packed and Crated Shipping Specification

Volume: 0.50m³

Gross weight: 30kg

Height: 0.550m

Width: 1.000m

Depth: 0.500m