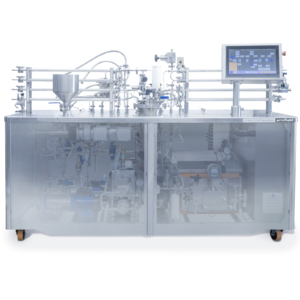

FT140X – Mixing vessels

Armfield FT140X Multipurpose Mixing Vessels are designed and constructed using high-quality hygienic industry standard materials. These tanks are available in three models of varying configurations (see table) and are available in 50l and 100l volumes. All three models have an internal surface made of AISI 316 stainless steel.

Description

Armfield FT140X Multipurpose Mixing Vessels are designed and constructed using high-quality hygienic industry standard materials. These tanks are available in three models of varying configurations and are available in 50l or 100l volumes. All three models have an internal surface made of AISI 316 stainless steel.

These tanks have been designed for industrial applications and are ideal for product storage and formulation in factory and pilot plant environments.

All tanks are supplied with an anti-dust cover, which is connected to an electronic safety switch. This ensures mixing only takes place when the lid is closed unless you choose to override. They also come with an anti-oxidant lid and a visualisation column for level indication.

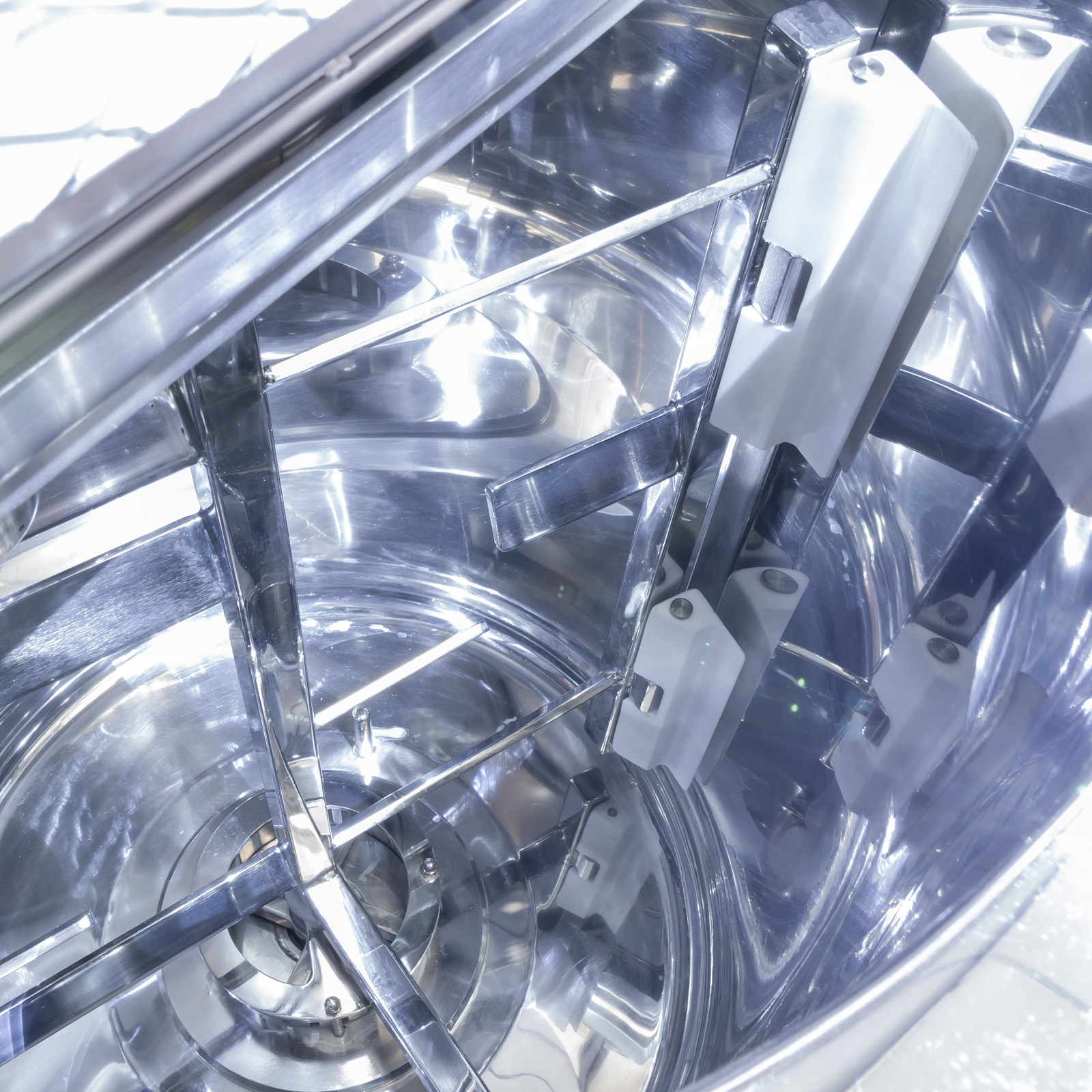

The agitators are manufactured with alternately rotating racks (optional), making these vessels ideal for preparing and mixing dense products like creams, soups and broths.

Electronically controlled variable speed turbo-emulsifiers with holes or slots can also be used for agitation.

Cooling in the jacketed vessel is achieved using an external water supply or by means of a closed circuit cooling system.

The control panels are IP65 rated. They come complete with a manual override safety switch, temperature controller, indicator lamps, speed regulator, a fully protected Plexiglas casing and an emergency stop button.

Technical Specifications

Features & Benefits

- Temperature control option with water jacket (CFCR)

- IP65 rated control panels

- Modes – setting and switching process parameters using touchscreen and the facility to set and recall process programmes

- Electronic control speed for mixing agitator (20-60 rpm)

- Datalogging to record process data

- 50 or 100l tanks available as standard

- CIP spray ball as standard

- 316L stainless steel finish for all product contact surfaces

- Low speed agitator with two direction paddle as an option

- 316 stainless steel drain valve

- High shear, variable speed emulsification mixer as option

- Safety switch on lid

- Alarm and controls indicators on touch screen

- VPN connection

- Interchangeable Teflon scrapers

- 316L stainless steel thermostatic chamber

- Electrical heating

- Cooling water inlet and closing valve

- Water jacket level overflow

- Insulation with stainless steel cladding

- Electronic temperature indicator and controller

Vessel Type – Description

CFC – Non jacketed vessel with variable speed agitator

CFCR – Jacketed vessel with variable speed agitator, heaters and temperature controller

CCT – Jacketed vessel with variable speed agitator, high shear emulsifier, heaters and temperature controller

Electrical Supply:

Single phase or 3-phase depending on the unit (see ordering codes)

Water supply for jacketed vessels

Drainage

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 1.7m³

Gross Weight: 250Kg

Length: 1.80m

Width: 1.00m

Height: 1.40m

FT140-50-CFC-A 220-240V/1ph/50Hz/10A

FT140-50-CFC-G 220-240V/1ph/60Hz/10A

FT140-100-CFC-A 220-240V/1ph/50Hz/10A

FT140-100-CFC-G 220-240V/1ph/60Hz/10A

FT140X-50-CFCR-A 220-240V/1ph/50Hz/14A

FT140X-50-CFCR-G 220-240V/1ph/60Hz/14A

FT140X-100-CFCR-A 220-240V/1ph/50Hz/23A

FT140X-100-CFCR-G 220-240V/3ph/60Hz/23A

FT140X-50-CCT-A 220-240V/1ph/50Hz/21A

FT140X-50-CCT-G 220-240V/1ph/60Hz/21A

FT140X-100-CCT-A 220-240V/1ph/50Hz/29A

FT140X-100-CCT-D 208-220V/3ph/60Hz/29A

Three-phase variants of these systems are available to reduce the requirement for current.

Specific supply protection is required. Please request information specific to the system you purchase prior to preparing your laboratory or pilot plant.