FM52 – Gear Pump Demonstration Unit

Two gear wheels operate inside a casing. One is driven while the other rotates in mesh with it. The liquid is carried around in the space between consecutive teeth and then ejected as the teeth mesh.

Description

Two gear wheels operate inside a casing, one is driven while the other rotates in mesh with it. The liquid is carried around in the space between consecutive teeth and then ejected as the teeth mesh. The pump has no valves and it is a positive displacement pump and will deliver against high pressures. The output is a more even flow than that of a reciprocating pump and it is particularly suitable for high-viscosity fluids.

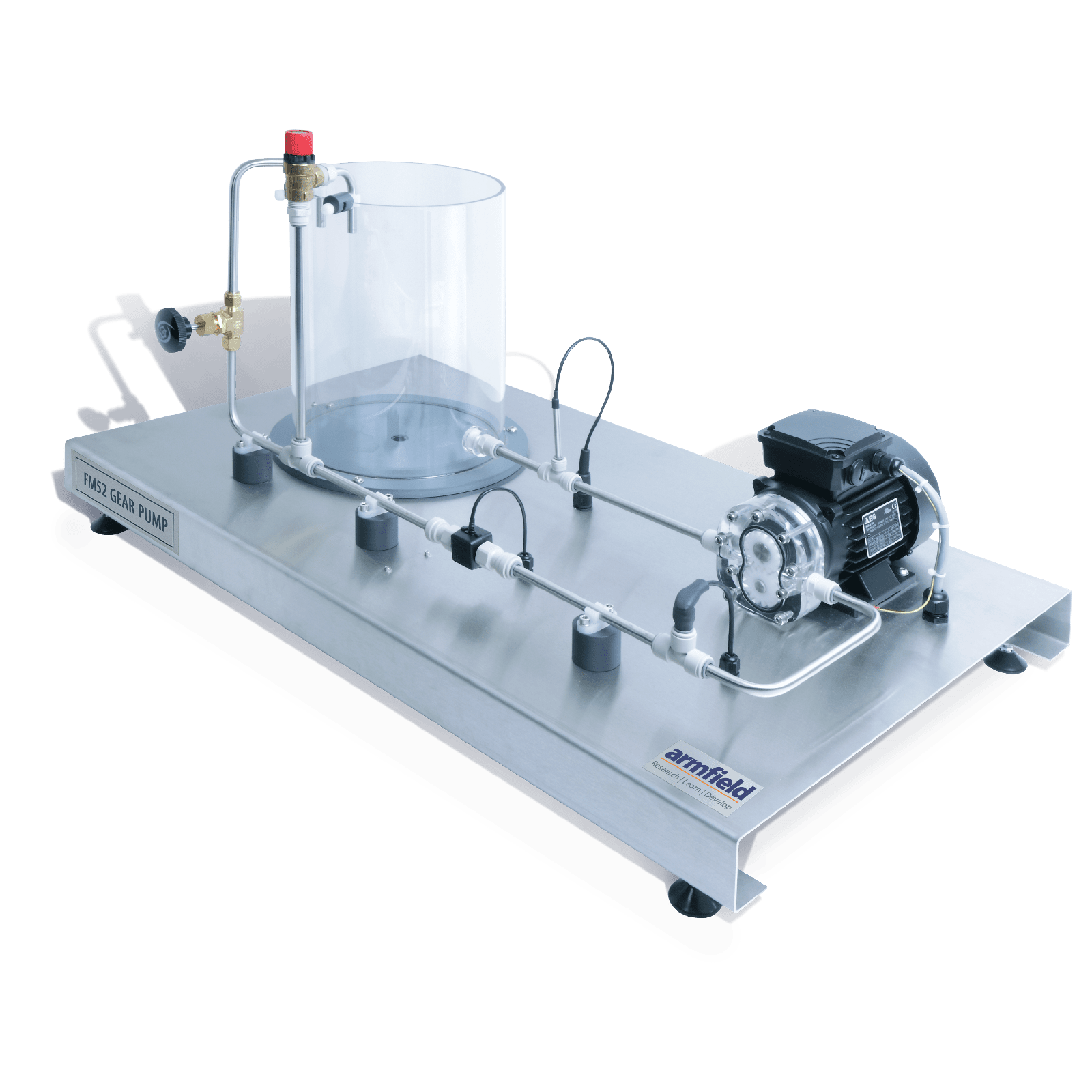

A motor-driven gear pump mounted on a stainless steel plinth with a water reservoir and pipework for continuous circulation. The pump head and the water reservoir are manufactured from clear acrylic for maximum visibility.

A manually operated valve at the pump outlet allows control of the flow and a pressure relief valve protects the operator and the equipment. Electronic sensors measure the pump outlet pressure, the flow rate and the water temperature.

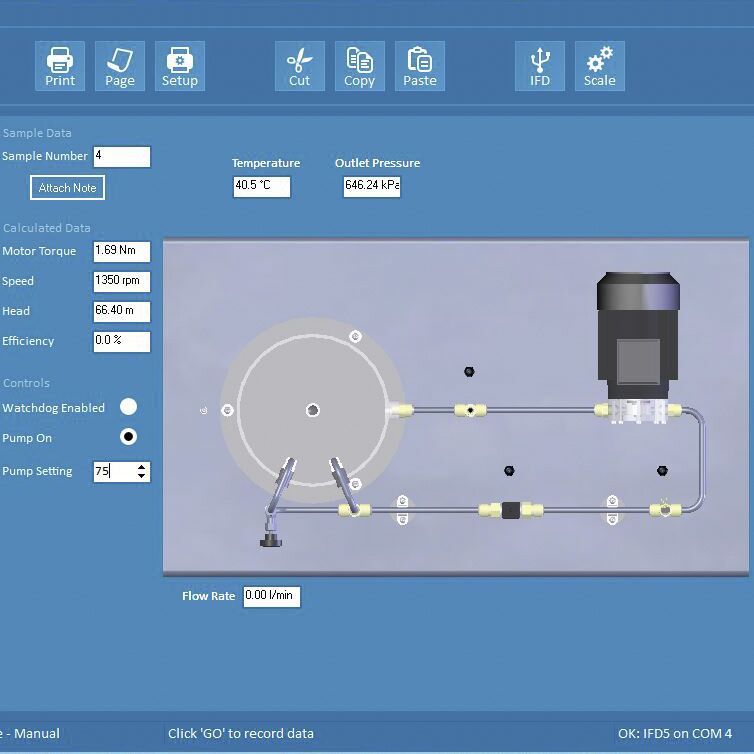

The pump speed is accurately controlled by an advanced electronic inverter within the IFD7 (an essential accessory). This inverter also calculates the torque produced at the motor drive shaft, allowing the power used by the pump to be derived.

The IFD7 also provides the conditioning electronics for the sensors and allows their readings to be displayed on the computer software.

Technical Specifications

Max flow rate: 6.5 l/m typical

Max head: 25

Max pump speed: 1,800rpm

Motor power rating: 250W

Gear Diameter: 38mm

Pressure sensor: 0 to 100psi

Pressure Relief Valve: 3bar

Features & Benefits

- Demonstration of a gear pump in operation

- Measurement of constant-speed pump performance, including the production of characteristic curves of outlet pressure against:

– Flow rate

– Motor shaft power

– Pump speed

– Pump efficiency

– Volumetric efficiency - Comparison of student calculations with computer results

- A small-scale gear pump demonstration unit comprising of a water reservoir, pump, control valve, relief valve and interconnecting pipework, all mounted on a stainless steel base

- Equipped with electronic measurement sensors for pump head pressure, flow rate and water temperature

- Transparent pump head for visibility

- Capable of being linked to a PC (not supplied} via a USB interface console (an essential accessory), which does not require internal access to the computer. Also enables interfacing to other software packages

- Supplied with software providing full instructions for setting up, operating, calibrating and performing the teaching exercises. Facilities for logging, processing and displaying data graphically

- Offers a complete teaching package of coursework and laboratory investigation

Armfield IFD7

Armfield IFD7

Software requires a computer running Windows XP or above with a

USB port (computer not supplied by Armfield)

Volume: 0.75m³

Gross weight: 100kg

Length: 0.88m

Width: 0.51m

Height: 0.41m

FM52

IFD7-A: 220-240V / 1Ph / 50Hz

IFD7-G: 220-240V / 1Ph / 60Hz