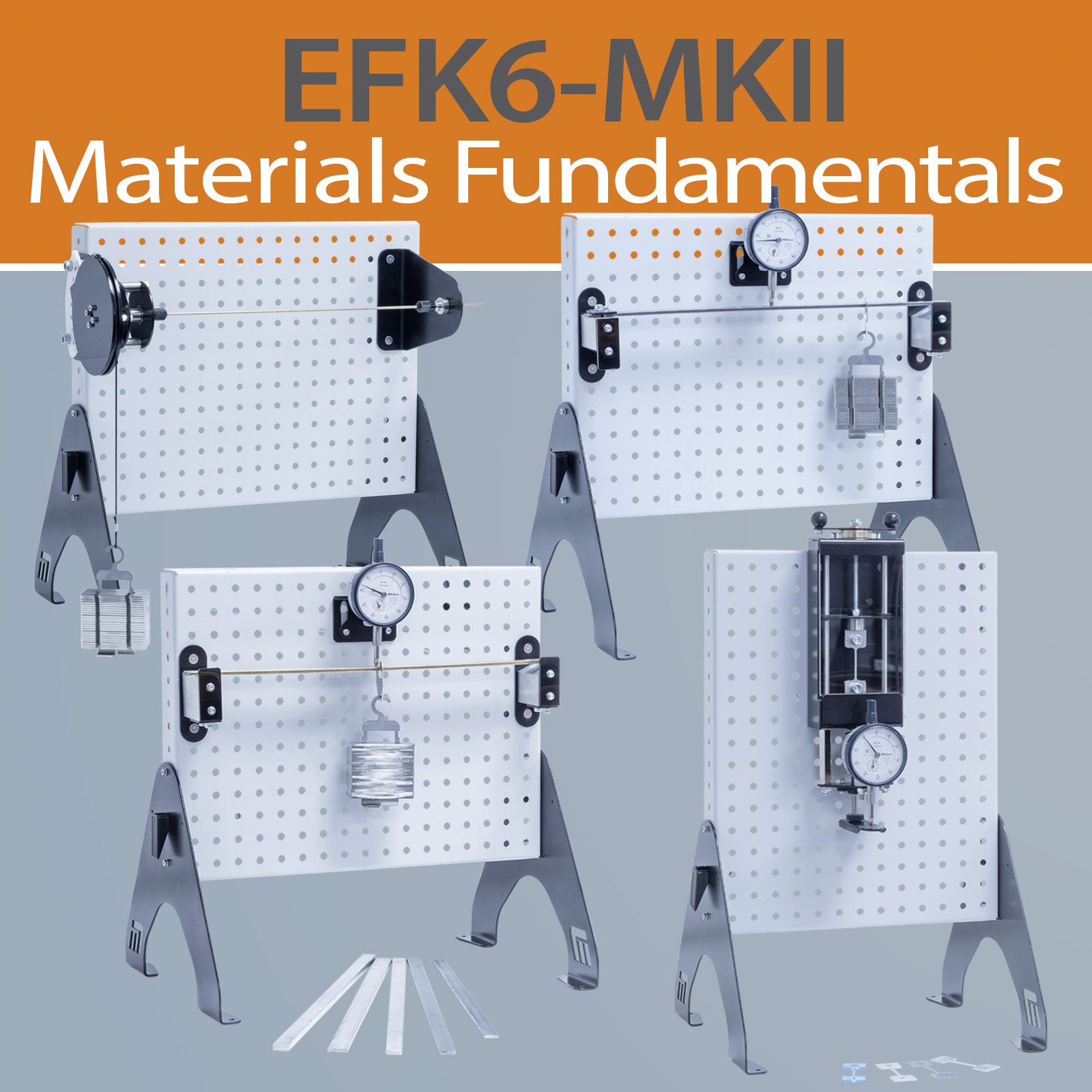

EFK6-MKII Materials Kit

The Engineering Fundamentals EFK6-MKII Materials fundamentals kit is designed to enable students to gain an understanding of the fundamentals of engineering by the process of learning via hands-on experimentation.

Practical experience allows students to see the real-world application of theoretical knowledge, leading to a deeper and more comprehensive understanding of engineering principles.

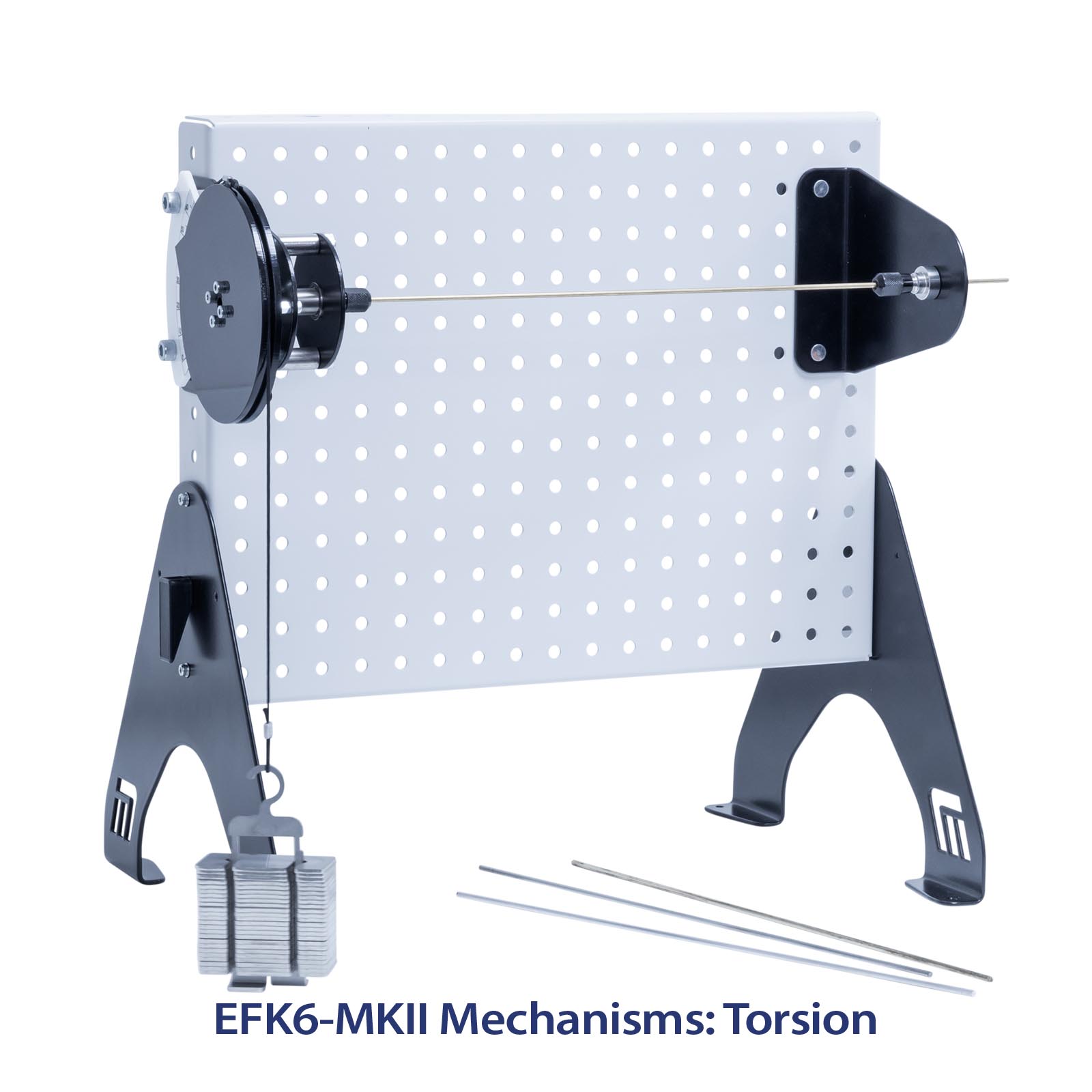

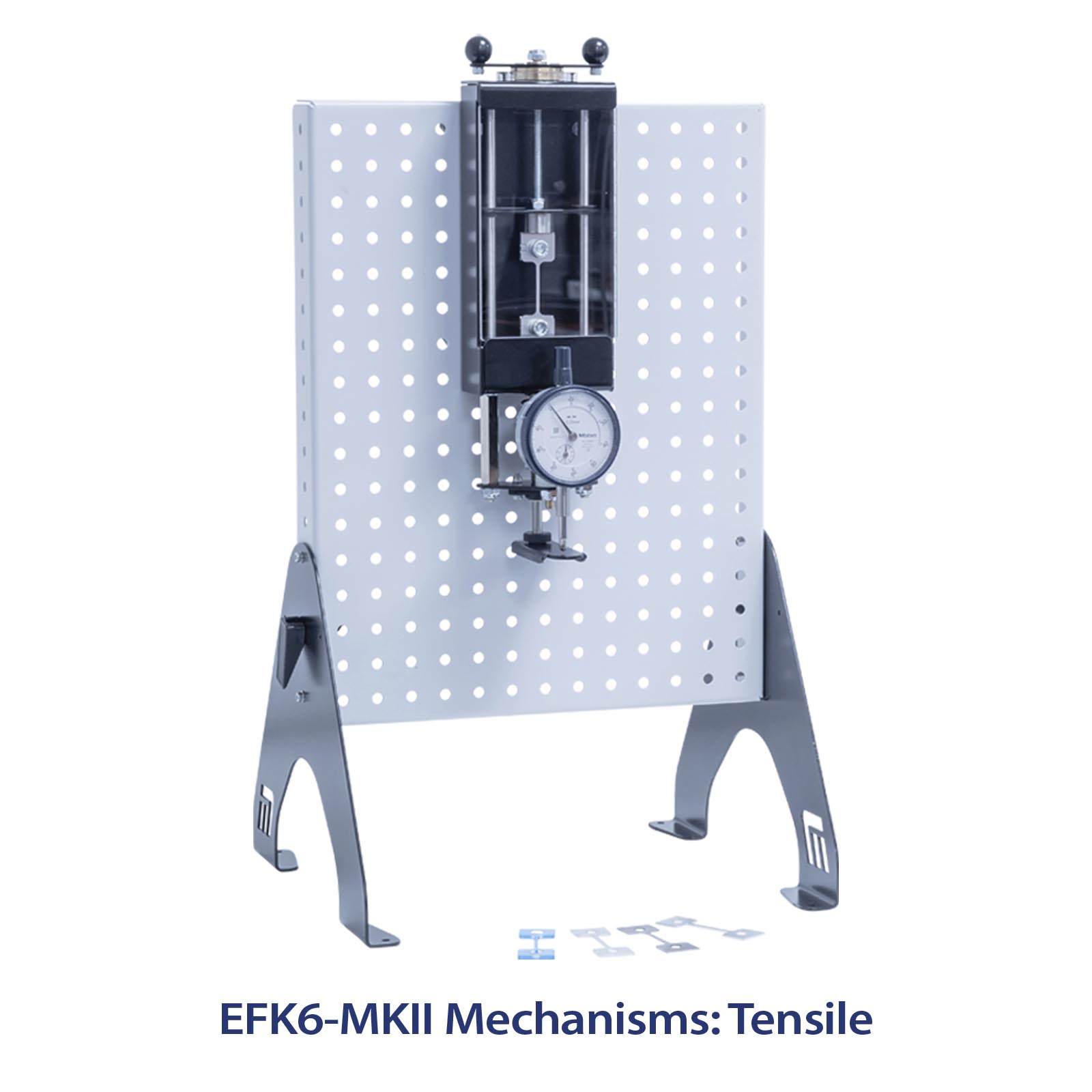

The modular kit is supplied in conjunction with a multifunctional base unit enabling the student to conduct their own experiments in subjects such as types of supports, torque and torsion, tensile stress, tensile strain and shear strain.

Each kit is supplied with a highly visual user-friendly operational guide, enabling the student to understand the theory of the subject by the application of practical experimentation.

EFK6-MKII Materials Fundamentals Kit

Description

The Engineering Fundamentals EFK6-MKII Materials fundamentals kit is designed to enable students to gain an understanding of the fundamentals of engineering by the process of learning via hands-on experimentation.

Practical experience allows students to see the real-world application of theoretical knowledge, leading to a deeper and more comprehensive understanding of engineering principles.

The modular kit is supplied in conjunction with a multifunctional base unit enabling the student to conduct their own experiments in subjects such as types of supports, torque and torsion, tensile stress, tensile strain and shear strain.

Each kit is supplied with a highly visual user-friendly operational guide, enabling the student to understand the theory of the subject by the application of practical experimentation.

Bundled Learning For:

- STEM Education

- National Vocational Qualifications

- High Schools & Technical Colleges

- University Foundation Degrees

Topics Covered:

- Types of Supports

- Torque and torsion

- Tensile Stress and Tensile Strain

- Shear Strain

Technical Specifications

- Work Panel for Fundamentals 1

- Strain Head Assembly 1

- Torsion Fixed End Assembly 1

- Hanging Weights 2

- Magnetic Bracket Assembly 1

- LH Multi Support Assembly 1

- RH Multi Support Assembly 1

- Balance Slider Plate Assembly 1

- Tensile Tester Assembly 1

- Steel tensile specimen 10

- Aluminium 60/82 tensile specimen 10

- Plastic tensile specimen 10

- Shear test tongue 1

- Shear Chuck 1

- Aluminium wire 0.8mm diameter – 500mm length 3

- Copper wire 1.5mm diameter – 500mm length 3

- Brass test beam 1 – 350mm x 1/2in x 1/8in Flat bar 1

- Aluminium test beam 2 – 350mm ½” x 1/8″ flat bar 1

- Mild steel test beam 5 – 350mm x1/2in x 1/8in flat bar 1

- Knife edge hanger small 2

- Stainless steel round bar 1/8in diam. – 300mm 1

- Aluminium round bar 1/8in diam. – 300mm 1

- Brass round bar 1/8in diam. – 300mm 1

- Crash Foam 360mm x 260mm, thickness 25mm 3

- Aluminium tensile specimen 1050 10

- Aluminium test beam 350mm 5/8″x1/8″ 15.8mm x 3.2mm flat bar 1

- Hex allen key 5mm short arm 80mm long 1

- Hex allen key 3mm short arm 63mm long 1

- Aluminium test beam 350mm x ½” x ¼” 12.7mm x 3.2mm 6082T6 1

- Stainless steel test beam 3 – 350mm x 12mm x 3mm flat bar 1

- Mitutoyo dial indicator 1

- 5g hanging weights pack of 52

- Brass round bar 2mm – 350mm in length 1

Features & Benefits

Features

- Neatly presented in an easily identifiable and durable storage tray

- Trays have clear lids making it easy to see their contents.

- Accompanied by a detailed manual, including Student handouts and teachers notes with various practical exercises.

- Clear and concise assembly instructions for each experiment

- Multiple experiments per kit

- Toolless assembly

Benefits

- Enhanced Understanding of Concepts:

- Improved Problem-Solving Skills:

- Engagement and Motivation:

- Teamwork and Communication:

Contains one of each of the EFK6-MKII Materials Fundamentals Kit

EFK6-MKII Materials Fundamentals Kit

- EFK6-MKII Materials Torsion

- EFK6-MKII Materials Tensile

- EFK6-MKII Materials Shear

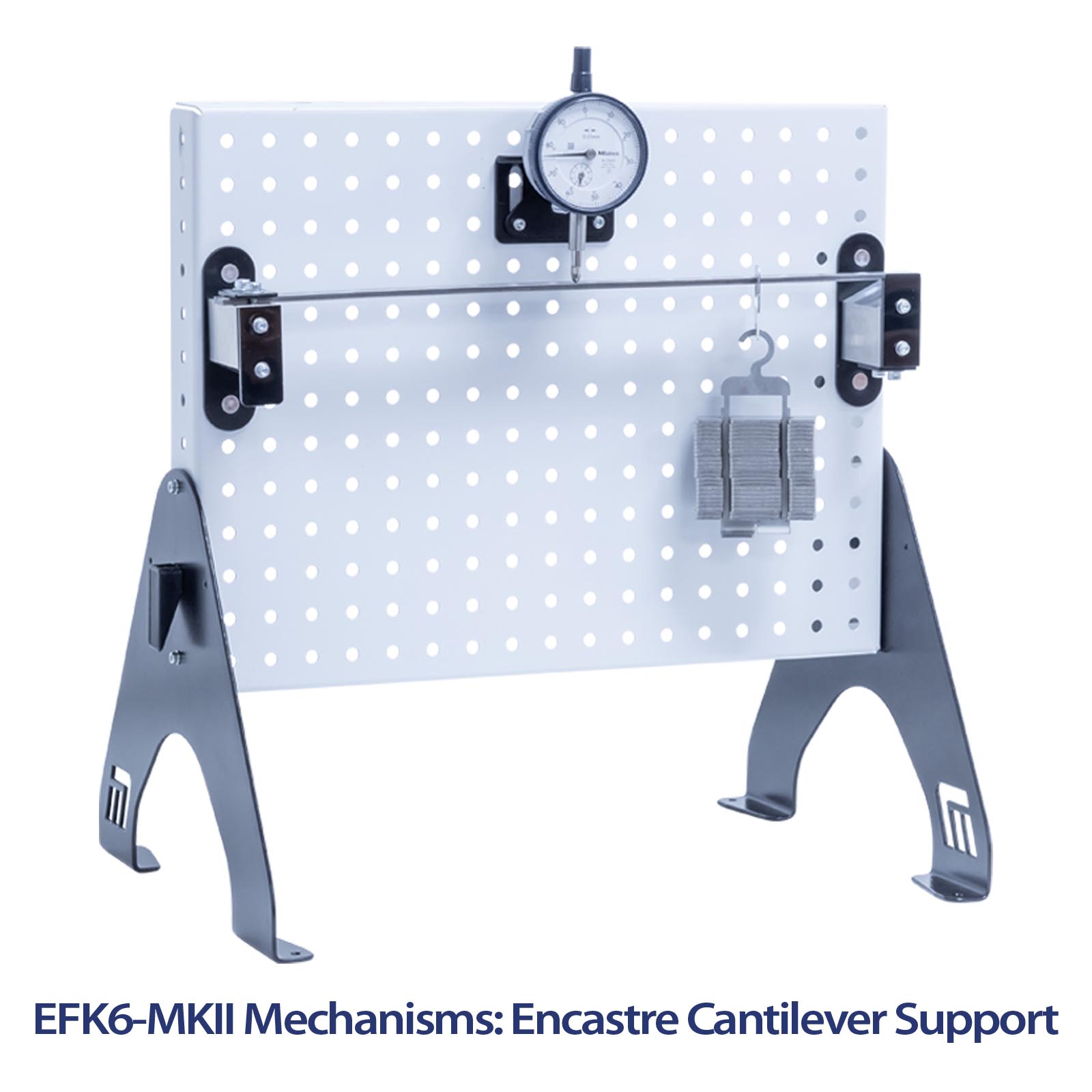

- EFK6-MKII Materials Encastre Cantilever Support

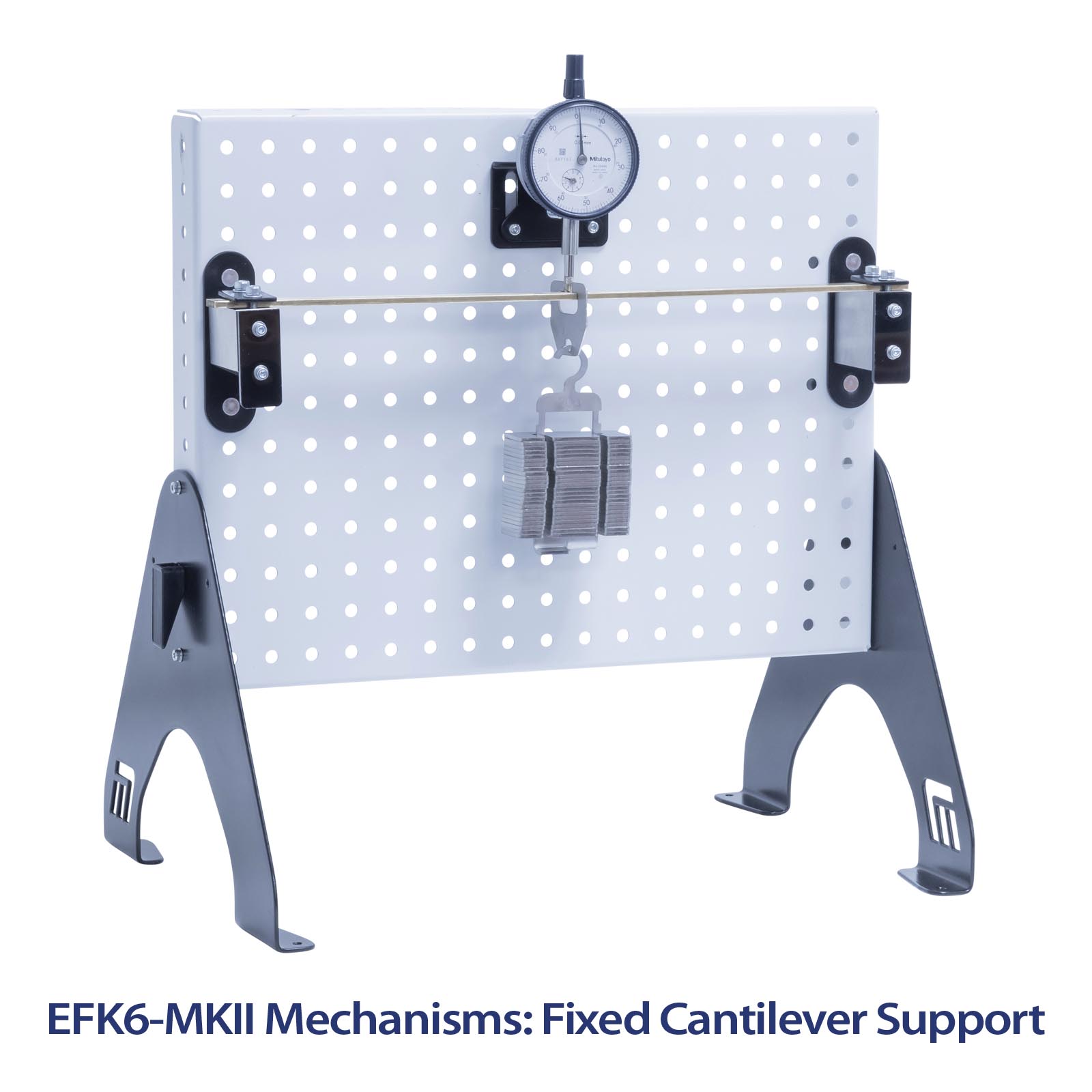

- EFK6-MKII Materials Fixed Cantilever

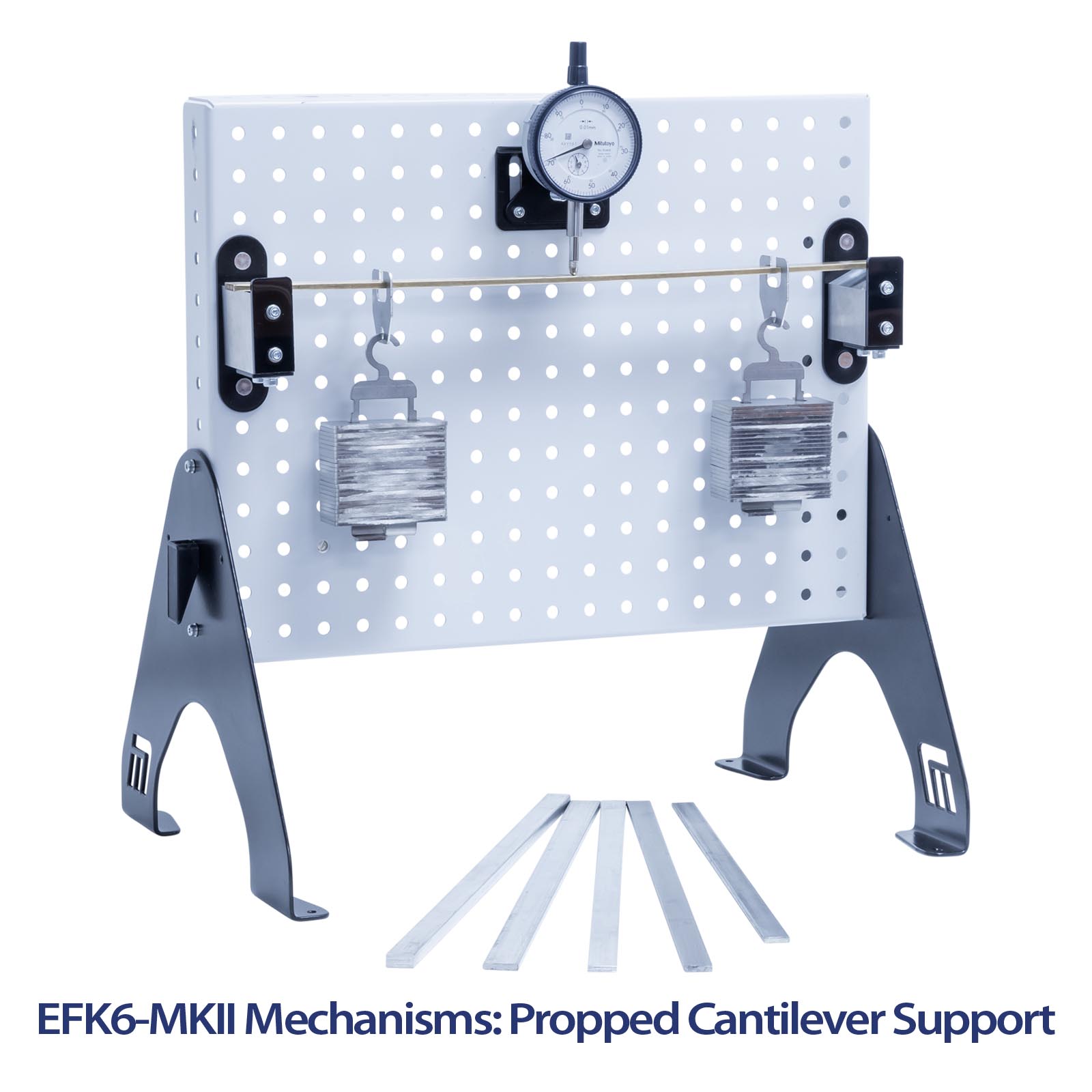

- EFK6-MKII Materials Propped Cantilever Support

Educational Content:

- distinguish between the following types of support:

- simple

- fixed

- cantilever

- propped cantilever.

- explain the meaning of the term Young’s modulus.

- use vernier callipers to measure the dimensions of a metal bar.

- use the formula ‘deflection δ = FxLᶾ / 48xExI’ to explain why the graph of δ vs F should be linear.

- explain why errors in measuring L will have a significant effect on the graph of δ vs F.

- outline three ways in which Young’s modulus can be obtained from the graph of δ vs F.

- re-arrange the formula ‘deflection δ= FxL3/48xExI’ so that the subject of the formula is load F.

- explain in qualitative terms the way in which the profile of a beam affects its rigidity.

- perform an experiment to compare the rigidity of beams of the same metal having different profiles.

- explain why the depth of the beam is more significant than its width in determining its rigidity.

- explain the significance of the constant K in the general formula for the deflection of a beam loaded at its centre.

- use a graph of deflection δ vs (F x Lᶾ /E x I) to obtain K for a given type of support.

- give three examples of common structures that use a cantilever beam.

- give the significance of the result that a graph of deflection δ vs L3 is linear.

- use the equation δ= F x a x (3L² – 4a²) / 24 x E x I’ to calculate the maximum deflection at the centre of a beam subjected to two equally spaced point loads.

- describe one example of the use of such a beam.

- explain the meaning of and distinguish between the terms torque and torsion.

- state the SI units of:

- torque,

- polar second moment of area,

- modulus of rigidity.

- convert a mass expressed in grams to kilograms.

- calculate the weight of a given mass given the local gravitational field strength.

- use vernier callipers to measure the diameter of a metal rod.

- convert angles measured in degrees into radians.

- calculate the torque exerted by a given force at a given distance from an axis of rotation.

- calculate the polar second moment of area for a rod of given diameter.

- understand the meaning of the multiplier ‘giga’.

- calculate the theoretical twist angle for a rod, given the torque, polar second moment of area, length and modulus of rigidity of the material.

- explain why a change in the diameter of the rod has such a large effect on the twist angle produced by a given torque.

- recognise that an equation of the form ‘y = m.x + c’ will generate a straight line when the ’y’ variable is plotted against the ’x’ variable.

- calculate the gradient of a straight-line graph in order to determine the modulus of rigidity of a specimen.

- explain what is meant by the elastic behaviour.

- describe the relationship between the length of a rod and the twist angle produced by a given torque.

- define the terms tensile stress and tensile strain.

- distinguish between elastic and plastic behaviour when a material stretches.

- understand what is meant by ‘zero error’ in a measuring instrument and be able to allow for it when taking readings.

- use the value of spring constant to calculate the force exerted by a compressed spring.

- explain what is meant by the terms:

- yield strength.

- ultimate strength.

- fracture

and recognise these on a graph of applied force vs extension.

- define Young’s modulus.

- give two reasons why this equipment is unsuitable for obtaining accurate values for Young’s modulus.

- explain what is meant by the terms strain hardening and necking and identify the regions where these occur on a graph of applied force vs extension.

- distinguish between the terms ‘ductile’ and ‘brittle’.

- distinguish between tensile stress and shear stress.

- process measurements and plot a graph of applied force vs extension, given results like those obtained in these investigations.

- EFK1-MKII Statics Fundamentals Kit

- EFK2-MKII Dynamic Fundamentals Kit

- EFK4-MKII Mechanism Fundamentals Kit

EFK6-MKII base unit with stand on which to build the experiment from the tray components (One base unit is supplied)

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.032m³ per tray

Gross Weight: 9kg

TRAY DIMENTIONS

Tray 1:

Length: 0.430m per tray

Width: 0.21m per tray

Height: 0.08m per tray

Tray 2:

Length: 0.430m per tray

Width: 0. 21m per tray

Height: 0.24m per tray

EFK6-MKII