EF-6.5 – Biomass Fuel Technology

EF-6.5 Biomass Fuel Technology tray covers the entire process of producing biofuels.

The Armfield EF-6.5 additionally covers production of biodiesel through transesterification of fats.

Description

EF-6.5 Biomass Fuel Technology tray covers the entire process of producing biofuels. It starts with the biological step of alcoholic fermentation. Afterwards the produced mash will be distilled with the help of the supplied condenser.

The final stage is the conversion of the produced biofuel into usable energy, such as electrical energy, using the provided Ethanol-fuel cell.

The Armfield EF-6.5 additionally covers production of biodiesel through transesterification of fats.

Technical Specifications

- 1 x Potentiometer module

- 1 x Motor module without gear

- 1 x Ethanol fuel cell module

- 1 x Plug with hose

- 1 x Yeast

- 4 x Bumpon transparent 5.0 mm height X 11.1mm diameter

- 1 x Propeller

- 1 x Laboratory thermometer

- 1 x Distilling head, 2 cores 75°, NS 19/26

- 1 x Condenser

- 1 x Alcoholmeter

- 1 x Erlenmeyer flask 1000ml

- 1 x Airlock

- 1 x Rubber stopper

- 1 x Areometer

- 1 x Beaker 250ml

- 3 x Test tubes

- 1 x Grip stopper

- 3 x Pasteur pipette

- 1 x Measuring cylinder 100ml

- 1 x Syringe 2ml

- 1 x Silicone ring

OPERATIONAL CONDITIONS

Storage Temperature: -10°C to +70°C

Operating temperature range: +10°C to +50°C

Operating relative humidity range: 0 to 95%, non-condensing

Features & Benefits

- Tray based solution that can be easily stored in the EF-WS workstation

- Simple plug and play operation

- Includes bioethanol and biodiesel production

- Includes an Ethanol-fuel cell for the generation of electrical energy out of biofuel

- Includes fundaments of basic electronic circuits

- Supplied with comprehensive teachers and students manual

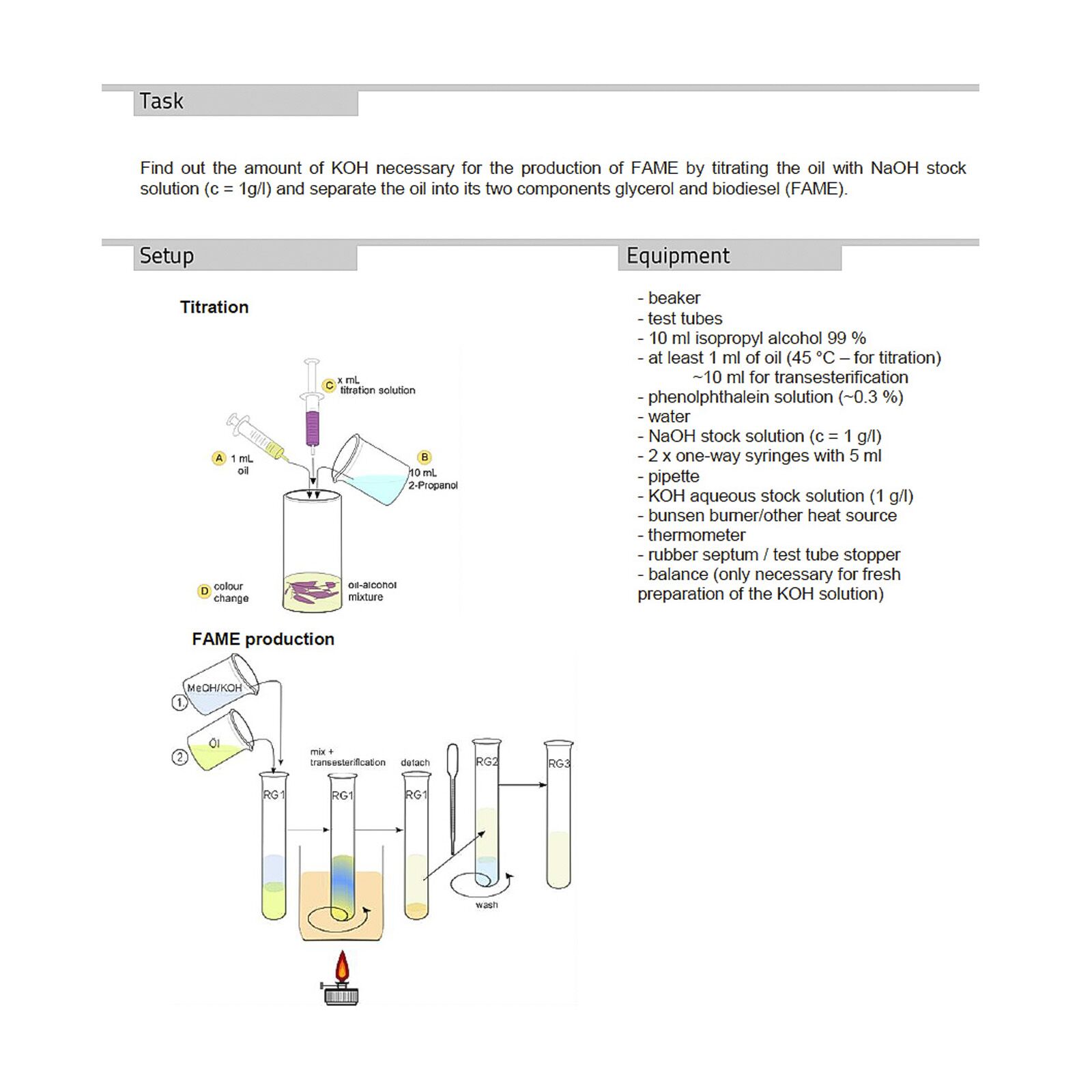

Part 1: Biodiesel production

- Transesterification from fat to Biodiesel (FAME)

- Determination of fat parameters

- Extraction of fats from foods and oil plants

Part 2: Alcohol fermentation

- Production of a mash/alcoholic fermentation

- Fermentation of different sugar types (including catalytic splitting of starch)

- Proof of fermentation gases

Part 3: Distillation and production of Bioethanol

- Distillation of mash

- Characteristics of the produced Ethanol

Part 4: Ethanol fuels

- Introduction Ethanol fuel cell

- I-V curve of Ethanol fuel cells

- Dependency of Ethanol fuel cells on concentration and temperature

- Energy balance of the whole process

- Physics

- Chemistry

- Biology

- Electrical Engineering

- Renewable Energies

EF-WS Engineering Fundamentals Work Station

- EF-6.8 Accessories Kit

- Clamp Stand (Not supplied by Armfield)

- Bunsen Burner (Not Supplied by Armfield

Electrical supply: 110-230V AC 50-60Hz

- Level and stable work surface

- Laboratory Clamp and Stand

- Bunsen Burner

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.021m³

Gross weight: 2.7Kg

TRAY

Length: 0.435m

Width: 0.315m

Height: 0.15m

EF-6.5: Engineering Fundamentals -Biomass Fuel Technology

EF-6.8 Accessories Kit

EF-WS Engineering Fundamentals Work Station