FT2 Hammer/Beater Mill

The Hammer/Beater Mill consists of a simple but sturdy overhung beater cross design with ease of accessibility and cleaning. The standard machine is of cast iron and occupies minimal bench space. A 1.5kW motor drives a beater cross at 8,000rpm above a curved replaceable screen. In its new form the grinding chamber is mounted above the motor and the shaft is driven by means of a short-toothed belt.

Description

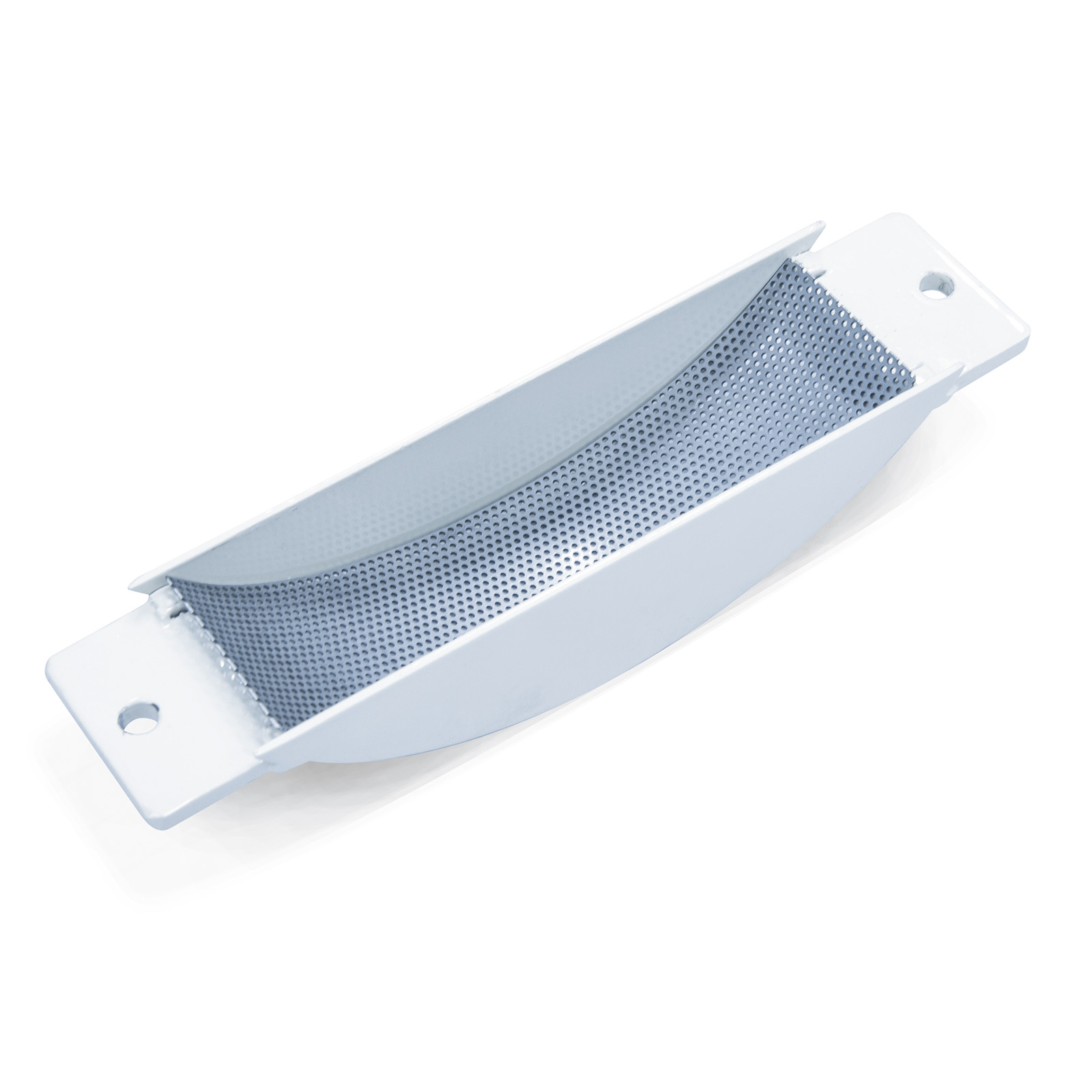

A system of milling seeds, nuts and other biomass using a rapidly rotating cross-bar. The size of the milled products is dictated by the aperture of the mesh at the base of the milling chamber.

The feed rate is passively controlled to avoid over feeding to the chamber.

Technical Specifications

- A self-contained mill using a reversible, high-grade steel beater cross

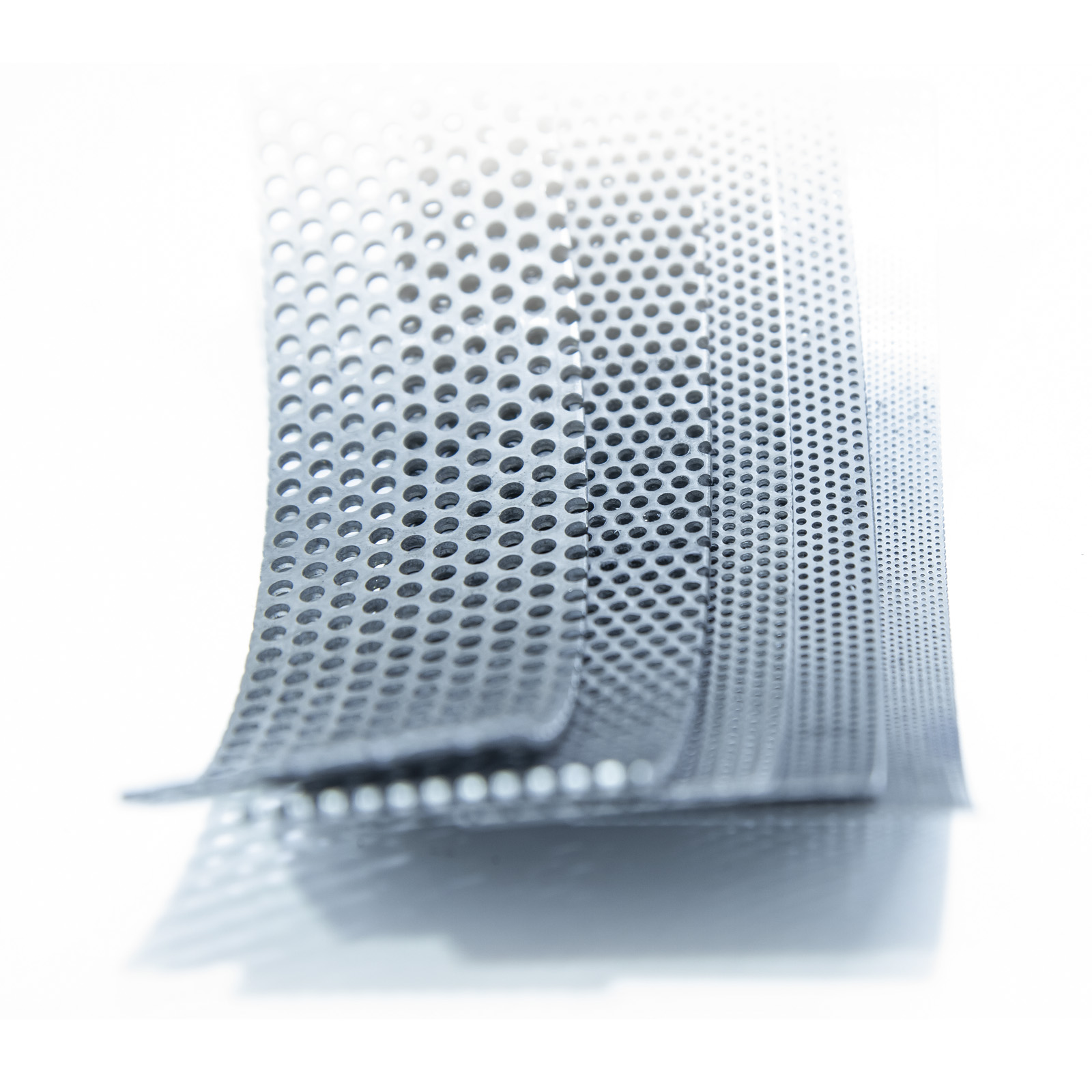

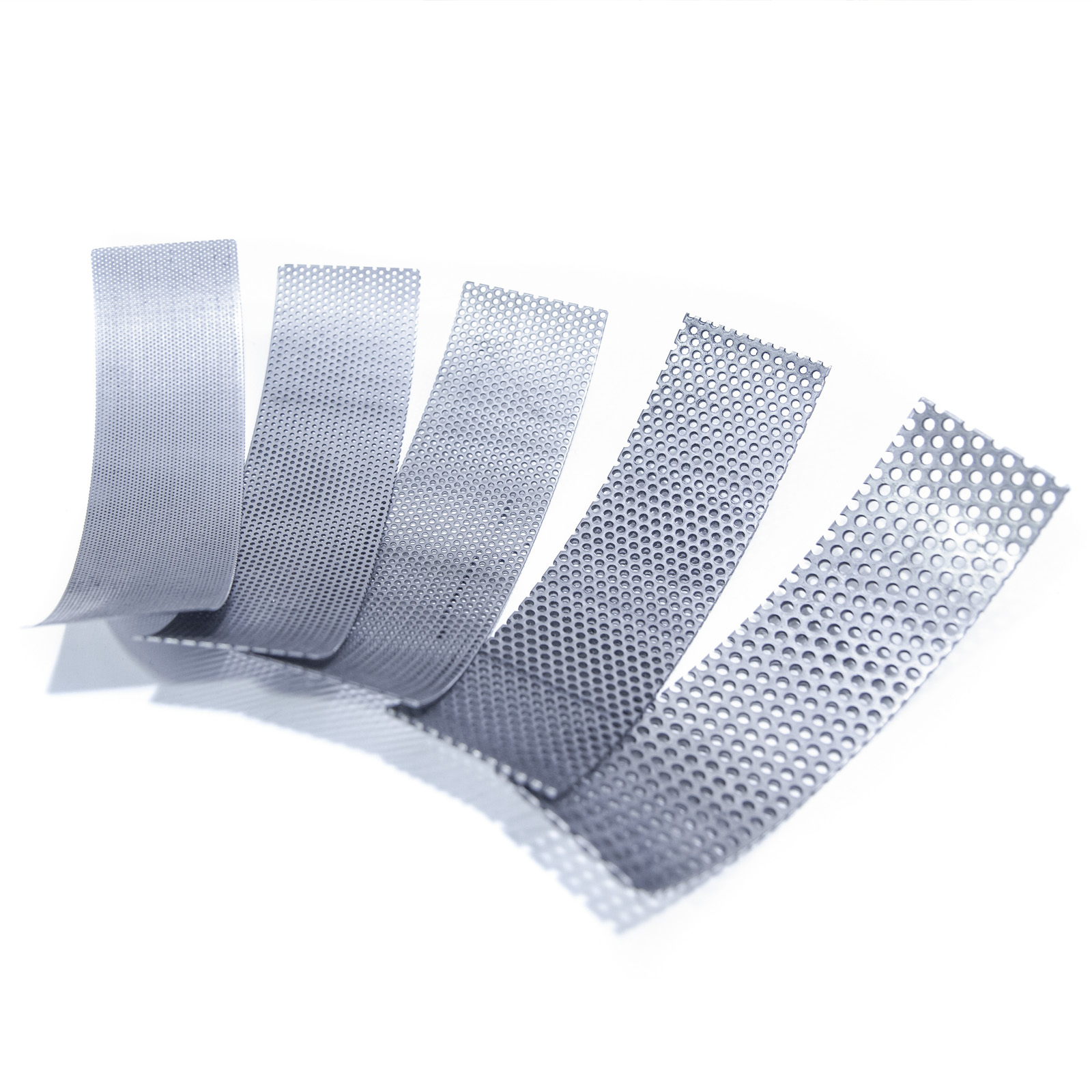

- Supplied with perforated plate screens ranging from 0.8mm to 3.0mm

- Fitted with a 1.5kW motor giving operating speeds of 8,000rpm via a toothed belth

- The unit is supplied with a detachable collection bag

- Front case is simply lowered for easy cleaning

- Safe design prevents accidental access of fingers, and the door in electronically interlocked

The arrangement has been specially designed to meet all the requirements of the UK Health and Safety at Work Act.

An electrically interlocked door, which must be opened in order to change the screens or to remove the collecting bag, disconnects the current. It is impossible to start the machine until this door has been closed. The inlet throat has been extended to prevent accidental injury to fingers as it is not possible to reach inside the grinding chamber.

To assist with cleaning, the front casing is fitted with a specially designed hinge so that the front can be dropped without the need to lift it away from the body of the machine.

Features & Benefits

- Easy access to processed Biomass

- Passive controlled feed system

- Changeable mesh plate for different size and pellets

- Sample On/Off control

- Lock-out safety switch to protect operators

Ground Sample Collecting System

For general laboratory grinding, the mill is supplied with bag collection. This is detachable from the metal frame which is clipped with the bag to the underside of the mill, and serves the dual purpose of collector and air filter.

Bearings

Roller and ball bearings are enclosed in a suitable housing and lubricated with high-speed grease, are of ample size to give trouble-free running over long periods.

- Seeds

- Nuts

- Other Biomass

This consists of a four-armed cross that revolves at a high speed and shatters or tears anything fed in through the throat from the small hand-feed tray illustrated. Manufactured from a high-grade steel alloy, it is carefully treated to obtain maximum hardness and strength, and is constructed so that it can be reversed when the leading edges are worn.

- The perforated plate-type screen is fitted in the bottom section of the grinding chamber, and this regulates the size of the ground product

- With each machine two cast iron screen frames are supplied together with one each of eight perforated plate screens having hole diameters 0.8, 1.0, 1.25, 1.5, 2.0, and 3.0mm

Packed and crated shipping specifications

Volume: 0.45m³

FT2: 120Kg

Length: 0.68m

Width: 0.41m

Height: 0.76m

FT2-A: 220-240V / 1ph / 50Hz

FT2-F: 220V / 3ph / 60Hz