W7 MKII Model Sedimentation Tank

This unit has been designed to demonstrate the hydraulic characteristics and settling efficiencies of a model settling basin. Although scale-up to industrial size sedimentation tanks is difficult, relevant deductions can be made as to how nonuniform flows occur and how these interact with the settling characteristics of particular suspensions.

Description

The W7MkII has been designed to demonstrate the hydraulic characteristics and settling efficiencies of a model settling basin. Although scale-up to industrial size sedimentation tanks is difficult, relevant deductions can be made as to how nonuniform flows occur and how these interact with the settling characteristics of particular suspensions.

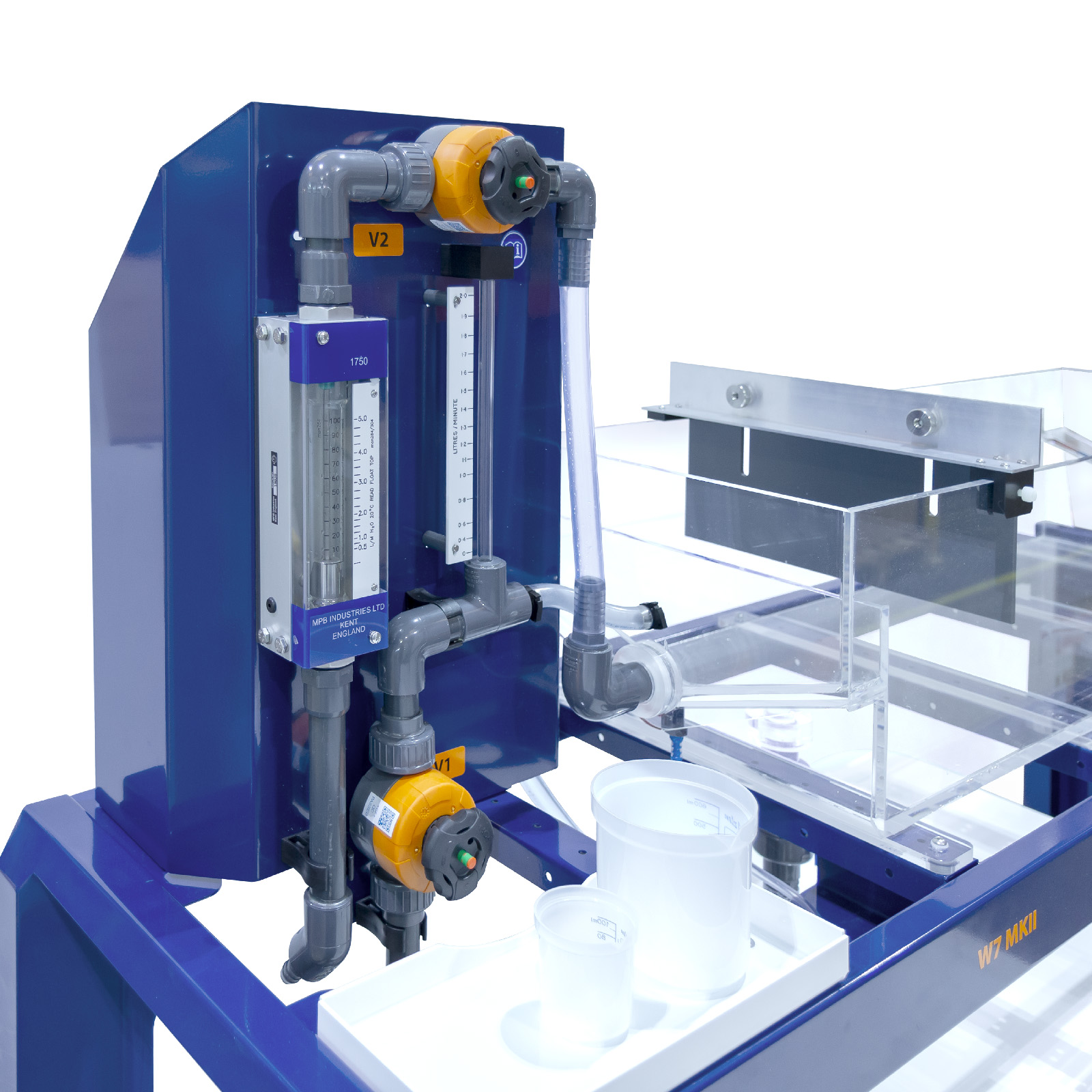

Water is taken from the laboratory mains supply and is fed to the settling tank via a flow meter. For studies of sedimentation, slurry is prepared in a sump tank and pumped via a specially designed flow meter to join the fresh water stream just before entry to the settling tank.

Well-mixed slurry of known concentration and flow enters the tank uniformly under the inlet weir. This may be comparatively analysed by using Armfield sedimentation studies apparatus (W2-MKII) or the Imhoff cone technique.

The sump tank is continually agitated by a flow sparging device to prevent settling of solids during an experiment.

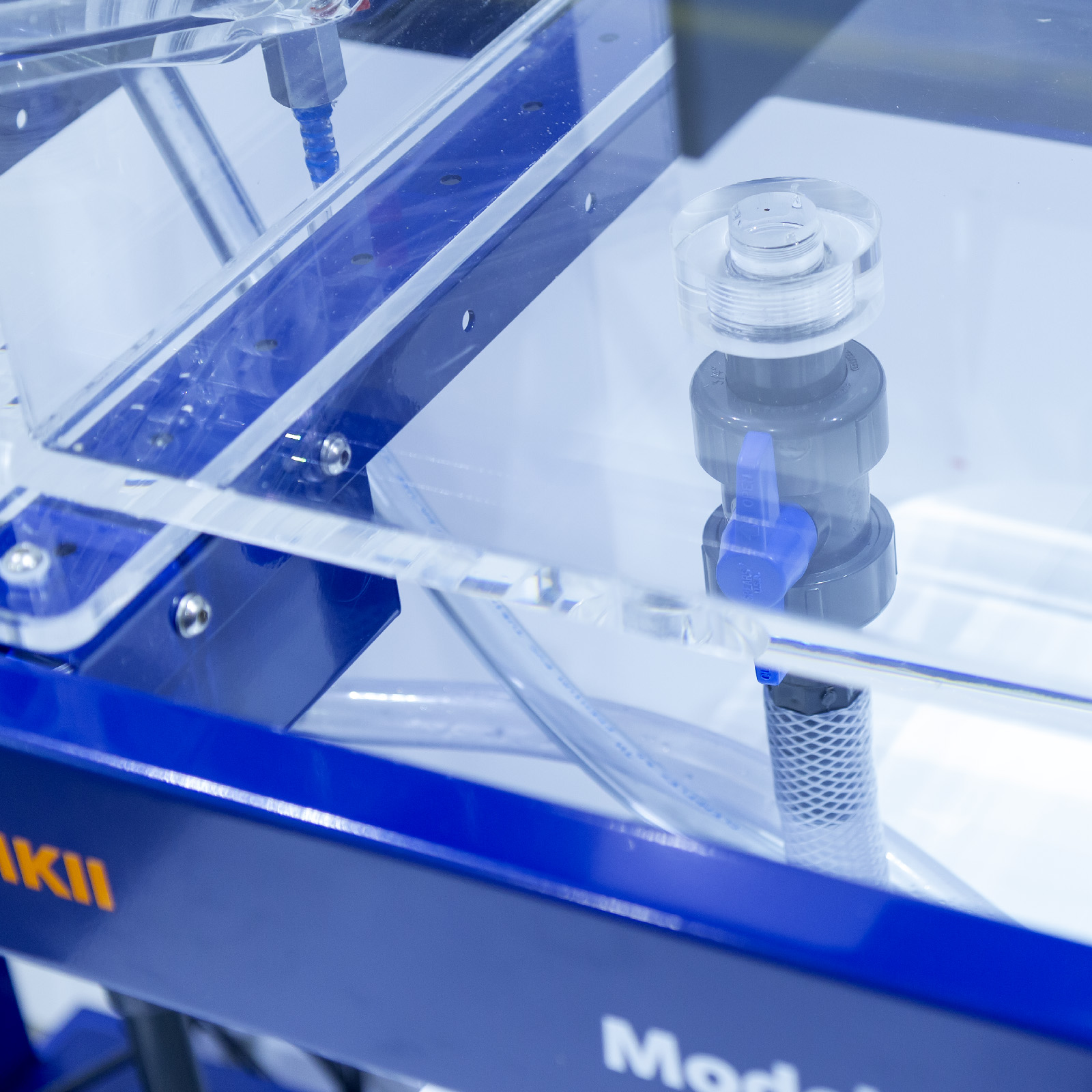

For hydraulic tracer and visualisation studies, an accurate dye injection system is provided. A known volume of dye solution is injected just before the entry to the settling tank.

Technical Specifications

Sedimentation tank: 97L

Acrylic settling tank: 1.05m x 0.35m x 0.2m

Feed tank capacity: 120L

Sediment flowmeter range: 0 – 2 L/min

Water flowmeter range: 0.5 – 5 L/min

Pump flow rate: 60 L/min @ 15m head

Features & Benefits

- Metal framework with clear sedimentation tank

- Flow sparge device in the tank to keep slurry in suspension

- Operational manual with teaching exercises

- Measuring flow short circuiting and dead space using a tracer

- Comparison of real flow regimes with idealised flow models

- Effect of flowrate and baffle position on dispersion

- Measuring sediment removal efficiencies and relating these to hydraulic characteristics

- Effect of solid concentration on separation efficiency

- Use of the Imhoff cones for analysis

- Measuring flow short circuiting and dead space using a tracer

- Comparison of real flow regimes with idealised flow models

- Effect of flowrate and baffle position on dispersion

- Measuring sediment removal efficiencies and relating these to hydraulic characteristics

- Effect of solid concentration on separation efficiency

- Use of the Imhoff cones for analysis

- Handheld turbidity meter (ordering code: INST 060)

- Triple beam balance with 0.1g sensitivity (ordering code: INST 059)

- Sedimentation tank of 97L capacity

- 120L sump tank via a centrifugal pump.

- A flow sparge device in the sump tank keeps the slurry in suspension

- Both supplies are fitted with a flow meters. Mains water flow meter range is 0.5-5.0 L/min; slurry flow meter range is 0-2 L/min

- 1 X Burette mount

- 3 X 1L Imhoff cones

- 1 X Imhoff cones rack

- 1 X 600ml sample vessel

- 1 X 100ml sample vessel

- 2 X stiffener bar

- 1 X adjustable inlet weir

- 1 X 1L bottle, Armfield blue dye with COSHH sheet

- 25Kg precipitated Calcium Carbonate & safety data sheet

- Operational manual with teaching exercises

Electrical supply:

- W7MKII A: 220-240V /1 ph / 50Hz

- W7MKII G: 220V / 1ph / 60Hz

Spectrophotometer (not supplied), Calorimeter (covering Wavelengths 450nm to 700nm not supplied) or handheld turbidity meter (available for order)

Water supply: 5L/min @ 1 bar

Packed and crated shipping specifications

Volume: 2.9m³

Gross weight: 120Kg

Length: 2.13m

Width: 0.76m

Height: 1.63m

- W7-MKII-A

- W7-MKII-G

- INST 059 (optional)

- INST 060 (optional)