archive page

Tag: heat transfer

HT10X Heat Transfer/HT30X Heat Exchange Ranges

The Armfield HT10X Heat transfer range:

Includes 11 different accessories to demonstrate the three basic modes of heat transfer (conduction, convection, and radiation). A common service unit avoids unnecessary cost duplication for control and instrumentation.

Educational software, including mimic diagrams, real-time control, data logging, graph plotting is Included as standard with the service unit. Embedded software based PID control of heater and water flow control enables steady state to be achieved in less than two minutes which maximises the time during a laboratory session that the student can undertake experimentation.

The Armfield HT30X Heat exchange range:

Includes 7 different accessories representative of industrial heat exchangers to demonstrate air to water and water to water Heat Exchange (Tubular, Plate, Shell and Tube, Jacketed vessel, and Cross flow). A common service unit avoids unnecessary cost duplication for control and instrumentation. Educational software, including mimic diagrams, real-time control, data logging, graph plotting is Included as standard with the service unit.

Embedded software based PID control of hot and cold-water and computer-controlled reversing of one of the fluid streams for co-current and counter-current investigations maximises the time during a laboratory session that the student can undertake experimentation.

The flexibility of both systems allows the unit to be operated in a standalone environment.

For more information click here

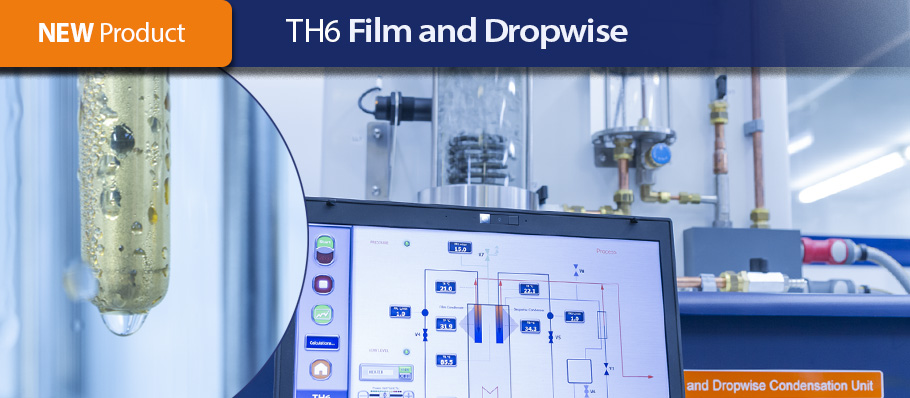

TH6 Film & Dropwise Condensation Unit

The Armfield TH6 Film & Dropwise Condensation Unit enables students to gain a knowledge of two fundamental condensation processes and how they affect efficiencies and heat transfer, found in industries such as steam power plants and distillation operations.

Used to demonstrate dropwise condensation, demonstrated by means of the condenser with a polished gold-plated surface and film condensation which forms on the matt copper surface of the second condenser.

The pressure in the main vessel can be reduced using a water jet pump to allow the student to observe it’s influence. Additionally, boiling point can be varied by a combination of changing the pressure in the system and controlling the heating power or water temperature by simple controls. The TH6 additionally includes the ability to undertake experimentation into the influence of non-condensing gases on the condensation processes.

Sensors record the temperature, pressure (vacuum) and flow rates at all relevant points. These measured values along with heater power are displayed via the unique ArmBUS software system which also includes inbuilt equations and a data export functionality for off-line analysis.

www.armfield.co.uk