FT25XA Scraped Surface Heat Exchanger Series

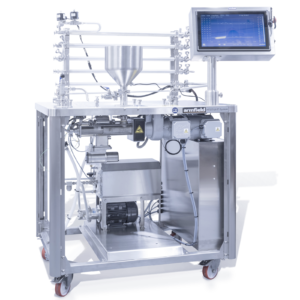

The FT25XA range of miniature-scale scraped surface heat exchangers has built-in control and flexibility with a graphic representation of the process on the touch screen control panel.

The operator can choose the parameters required for any particular formulation, these include margarine, shortening and ice cream processes.

The FT25XA has a number of configurations according to the required use.

Armfield miniature-scale technology is well established at offering developers the opportunity to run small trials, which provide enough information to enable scale-up to larger plant with confidence.

The formulations go through similar physico-chemical changes as they would in production plant and real time data logging permits results to be recorded and repeated.

Description

The FT25XA Scraped Surface Heat Exchanger Series, mounted on a stainless-steel frame is supplied with a large 15.4 inch HD touchscreen and ArmBUS control system. The working platform can accommodate one or two barrels (B) and a variable speed pinworker (P) alongside the hopper and connection ports.

The unit is housed in a Stainless Steel (304) cabinet with removable sides for easy access. It uses a refrigeration system supplied within the cabinet with a chilled, food-grade refrigerant, which is pumped through the barrel jackets. An air incorporation system with pump and control can also be added if required. Enhanced CIP system is also available.

Small batch sizes enable rapid product testing saving time, ingredients and utility costs.

Small batch sizes enable rapid product testing. Enhanced CIP facility available (FT52).

Note: For Scraped surface heat exchanger applications involving product heating, UHT, or combined heating and cooling, please enquire about our FT174XA – Modular Miniature HTST/UHT Process System.

Technical Specifications

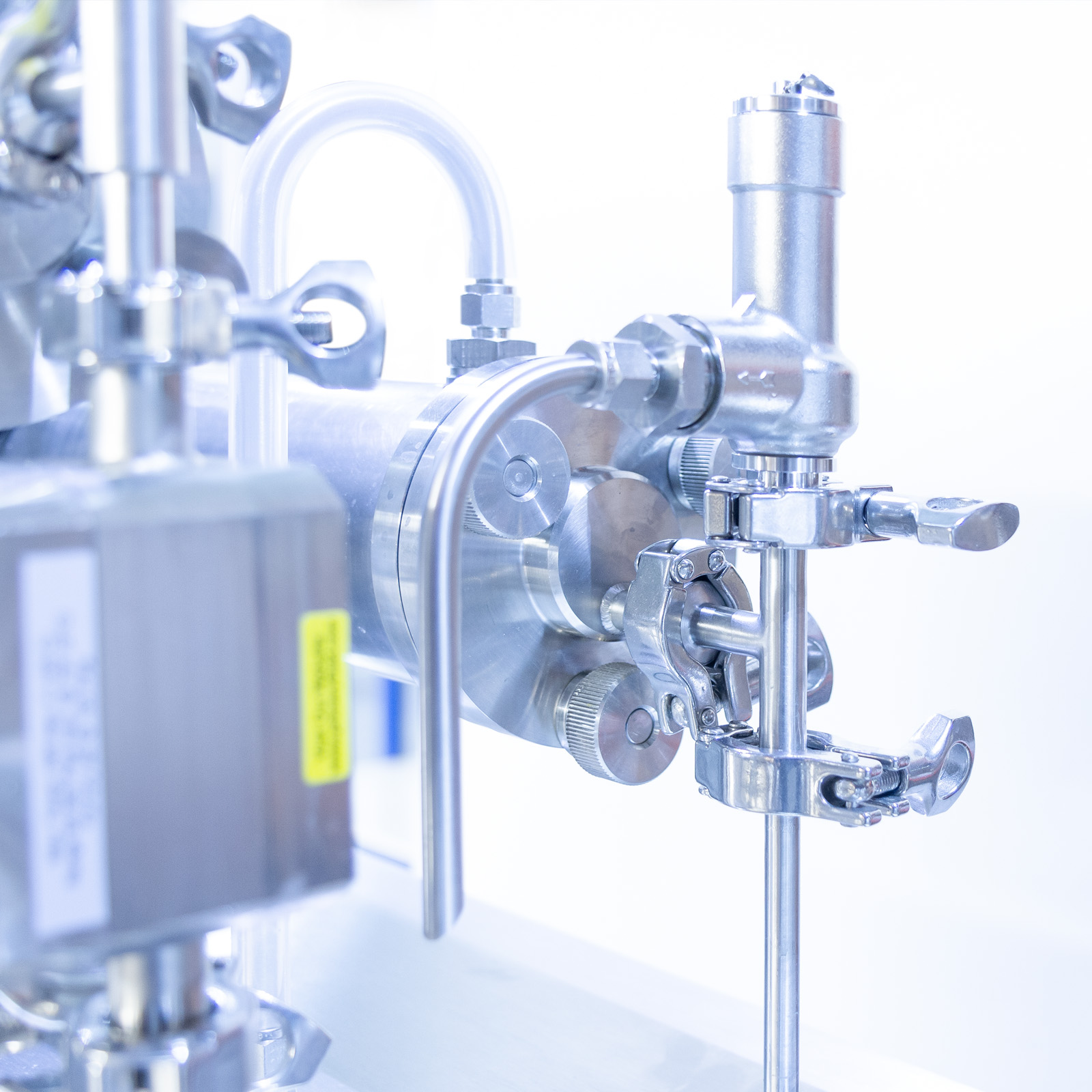

Heat Exchanger Barrel

Heat transfer area: 0.045m²

Shaft/barrel volume ratio: 1 : 3.5

Scraper blades: 4 PEEK scrapes along stainless steel shaft, 2 pairs with 180° separation

Barrel length: 0.35m

Barrel working pressure: 20 bar or 40 bar

Pinworker

No of pins on shaft: 36

No of pins on barrel: 36

Barrel/pinworker drives

Variable speed ac motors, inverter controlled

Speed range: 100-1400rpm

Refrigeration system

Food grade refrigerant: -25°C capability (Coolflow LVF50)

Feed pumps

Progressive cavity pump

Process throughput: Up to 0-20l/h, independent of back pressure

Particulate capability: up to 0.6mm

Fibre handling capability: up to 25mm

Air incorporation system: Air Pump with fine filter and digital flow controller

NOTE: Air supply is injected into the inlet of the feed pump.

Features & Benefits

- Duplicates full-scale process

- Fast, accurate new product development

- All process parameters under operator control for maximum flexibility

- Rugged and reliable units

- Only requires electricity and water to function

- Full control of barrel speeds to over 1400rpm

- Temperature control system incorporated

- Integral control panel enabling simple control and monitoring of all major variables

- Enclosed self-contained, mobile, stainless steel service cabinet for easy cleaning and wash down with removable panels

- Stainless steel barrel with PEEK scrapers

- Hygienic design

- Made from 316 stainless steel

- In cabinet refrigeration

Available:

- Variable speed pinworker for margarine and soft spreads

- Air incorporation system

- Computer data logging facility

- Integrated CIP Pump

Control Panel

The splashproof, full colour touch sensitive screen with diagrammatic representation of the process. It shows variables such as product feed pump rate, barrel and pinworker speed, temperature and pressure, which are all under operator control. Process data is displayed in real time and can be logged to a PC running the Windows™ operating system. Note: For Scraped surface heat exchanger applications involving product heating, UHT, or combined heating and cooling, please enquire about our FT174X – Modular Miniature HTST/UHT Process System.

Windows™ Data Capture Software

The FT25XA can data log all operational parameters when activated by the operator. The data will be stored in discreet data files which can be downloaded to a USB stick to allow for offline analysis using spreadsheets.

Supplied as standard, the FT25XA can data log.

Continuous Margarine Crystalliser

FT25XA-20BAR with FT25XA-20BAR-BP: One barrel and one pinworker.

FT25XA-20BAR with FT25XA-20BAR-BBP: Two barrels and one pinworker. A resting tube for product settling and food grade refrigeration unit for process cooling are supplied. A range of oil emulsions can be processed.

Continuous Ice Cream Freezer

FT25XA-20BAR with FT25XA-20BAR-B and FT25XA-20BAR-AIR: One barrel Air incorporation via a small air compressor and refrigeration. Overrun can be achieved up to 300% (dependant on product).

Combined Ice Cream and Margarine System

FT25XA-20BAR with FT25XA-20BAR-BBP and FT25XA-20BAR-AIR: Two barrels, one pinworker plus air incorporation and refrigeration.

- FT25XA-20BAR-52 – CIP Pump for 20 bar system

- FT25XA-40BAR-52 – CIP Pump for 40 bar system

- FT140X Mixing Vessel

The FT25XA utilises a cleanable touchscreen HMI with intuitive displays. All process parameters can be accessed and changed via the process HMI screen including coolant temperature, individual motor On/Off and rotational speeds and, where fitted, air incorporation flowrate. The process screen also incorporates key alarms to inform the operator of events preventing operation such as over pressure.

Realtime data is displayed from sensors and other devices providing the operator with instantaneous temperatures, pressure as well as motor currents and RPMs.

A graphing screen can also be called up where individual outputs can be displayed on a graph.

Electricity supply: (see ordering codes)

Water supply: For refrigeration cooling Cooling water supply with flow rate of 3l/min @ 3bar and ≤20°C

Packed and created shipping specifications

Volume: 2.1m³

Mass: 390Kg

Length: 1.01m

Width: 0.72m

Height: 1.45m

- FT25XA-20BAR-A 220-240v 1ph 50Hz (30 A max)

- FT25XA-20BAR-G 220-240v 1ph 60Hz (30 A max)

- FT25XA-40BAR-A 220-240v 1ph 50Hz (30 A max)

- FT25XA-40BAR-G 220-240v 1ph 60Hz (30 A max)