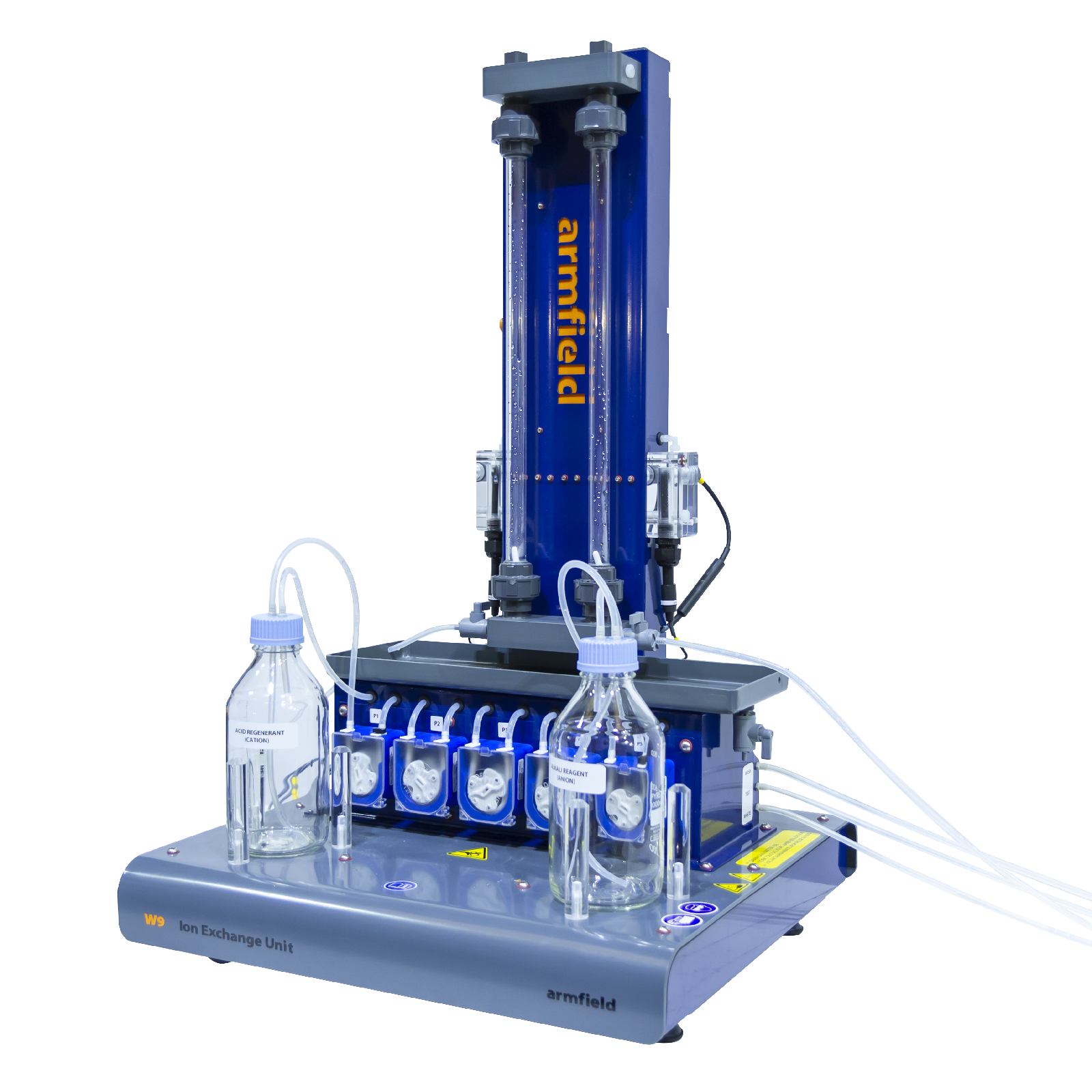

W9-MKII Ion Exchange Unit

Bench mounted unit designed to demonstrate the use of ion-exchange resins for either continuous water softening or demineralisation. The equipment is designed to show industrial operations such as ‘breakthrough’ and regeneration cycles.

Description

The unit consists of two vertical transparent columns containing the cation and anion resins, mounted on a support frame together with the necessary pumps, valves and sensors.

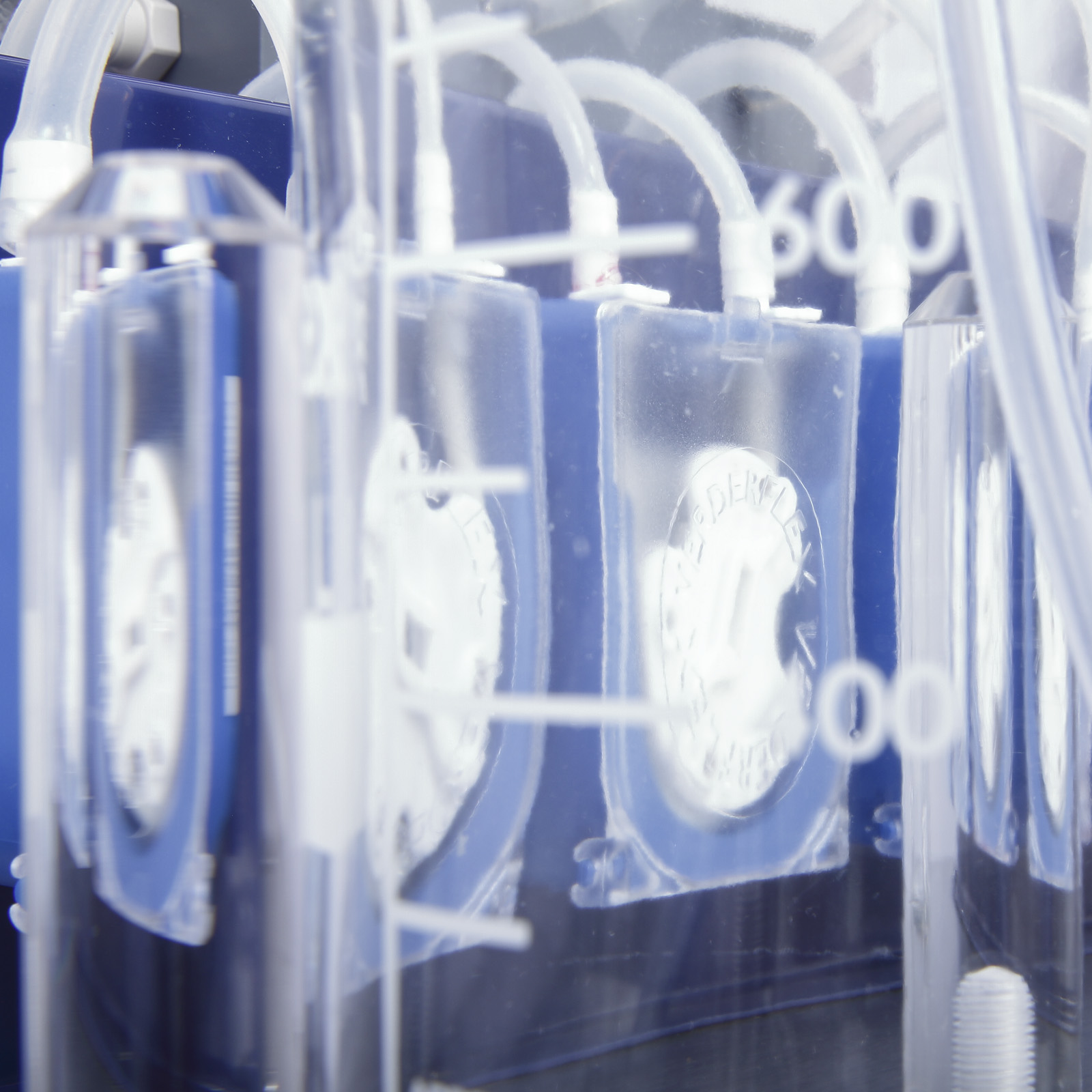

The arrangement of pumps and solenoid valves enables the flow configuration to be changed to demonstrate the various stages involved in the demineralisation or water-softening processes. Each stage of the process is selected by the operator using a PC and a mimic diagram for the appropriate stage displayed on the screen.

Conductivity, temperature and pH of the influent and effluent of the columns are measured using electronic sensors for data logging. The apparatus is supplied with a typical commercial cation and anion resin, but other ion-exchange materials (not supplied) may be used so that their characteristics, exchange capacity etc may be measured and compared.

Union couplings at both ends of the columns enable the column to be easily removed for maintenance and set-up without the need for tools. Regenerant, test and wash solutions are stored in separate containers to avoid cross-contamination, and effluents are fed to a waste-water tank for proper disposal.

Technical Specifications

2 x vertical columns: 16mm ID

Solenoid valves: 5 x Two-way valves (suitable for 10% HCl, 5% NaOH and 10% NaCl)

Pumps: 4 x 0-50mL (suitable for acid and alkali)

Pump: 1 x 0-75mL (suitable for acid and alkali)

PH sensors: 2

Conductivity/temperature sensors: 2 x 0 – 2mS/cm

Conductivity probes: 2 x 0 – 2mS/cm

Regenerant bottles: 2 x 1L

Waste-water container: 25L

Feed & wash water containers: 2 x 10L

Features & Benefits

- Transparent test section for demonstration

- Control and data logging via PC

- Inline or outlet conductivity and pH sensors

- 5 x solenoid valves for automatic selection of each part of the process

- Operational manual with teaching exercises

- Universal single-wire interface

- Water softening using cationic resin

- Exchange capacity of a cationic softening system

- Regeneration efficiency of a cationic softening system (regenerated using NaCl)

- Demineralisation using two-bed exchange (cationic resin and anionic resin used in series)

- Regeneration efficiency of a demineralisation system (regeneration cationic resin using HCl and anionic resin using NaOH)

- Exchange capacities of different resin materials (alternative materials not supplied)

- Electrical supply: supplied with a universal mains adaptor suitable for 100-240V / 1ph / 50-60Hz

- Software requires a computer running Windows XP or above with a USB port (computer not supplied by Armfield)

- Deionised water (not supplied)

- 5% sodium hydroxide (not supplied)

- 10% hydrochloric acid (not supplied)

- 10% sodium chloride (not supplied)

Water supply: Initial fill and drain

Packed and crated shipping specifications

Volume: 0.50m³

Gross weight: 40Kg

Length: 1.00m

Width: 0.50m

Height: 0.50m

W9MkII